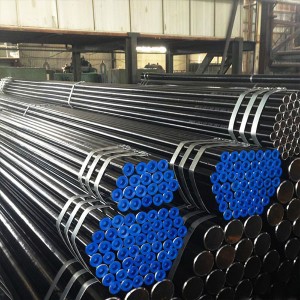

Pearlite Heat-Resistant 12CR 1movg High Pressure Alloy Tube

I-matrix yintsimbi ephantsi-i-alloy ekwazi ukumelana nokushisa kunye ne-pearlite okanye isakhiwo se-bainite. Kukho ubukhulu becala i-chromium-molybdenum kunye ne-chromium-molybdenum-vanadium series. Kamva, amanqanaba amaninzi (afana ne-chromium, i-tungsten, i-molybdenum, i-vanadium, i-titanium, i-boron, njl.) aphuhlisiwe, kwaye ukuqina kunye nokushisa kwenkonzo yentsimbi kuye kwanda ngokuthe ngcembe. Kodwa ngokuqhelekileyo inani elipheleleyo lezinto ezixutywayo liphezulu malunga ne-5%, kwaye isakhiwo sayo sibandakanya insimbi ye-bainitic ngaphezu kwe-pearlite. Olu hlobo lwentsimbi lunamandla alungileyo okukhwela ubushushu obuphezulu kunye nokusebenza kwenkqubo kwi-450~620℃, kwaye inokuqhuba kakuhle kwe-thermal, i-coefficient yokwandisa ephantsi kunye nexabiso eliphantsi. Isetyenziswa ngokubanzi ukwenza izixhobo ezahlukeneyo zokulwa nobushushu kuluhlu lwe-450~620℃. Njengemibhobho yensimbi yebhoyila yezikhululo zamandla, ii-impellers ze-injini zomoya, ii-rotors, i-fasteners, iinqanawa ezinoxinzelelo oluphezulu lokucoca ioyile kunye nemizi-mveliso yeekhemikhali, iibhoyila zobushushu obumdaka, iityhubhu zokufudumeza kunye neetyhubhu zokutshintsha ubushushu, njl.

[1] Intsimbi yentsimbi ephantsi yealloyi ekwazi ukumelana nobushushu.

Isetyenziswa kakhulu njengebhoyila iindonga zamanzi, izifudumezi ezinkulu, izifudumezi, ooqoqosho, iiheader kunye nemibhobho yomphunga, kunye neetyhubhu zokutshintshisa ubushushu zamandla epetrochemical kunye nenyukliya. Izinto ezifunekayo ukuba zibe nomda ophezulu wokunyuka, amandla ahlala ixesha elide kunye neplastiki ehlala ixesha elide, ukuxhathisa okulungileyo kwe-oxidation kunye nokuchasana nokugqwala, ukuzinza okwaneleyo kwesakhiwo kunye ne-weldability efanelekileyo kunye neempawu ezishushu kunye nezibandayo. Ubomi benkonzo obuyiliweyo bufikelela kwiiyure ezingama-200,000. Iimpawu eziphambili eChina yi-12CrMo, 15CrMo, 12Cr2Mo, 12CrlMoVG i-alloy tubes high-pressure, kunye ne-12Cr2MoWVTiB, ezisetyenziswa kuluhlu lwe-480~620℃. I-normalizing kunye ne- tempering isetyenziswa ngokubanzi kunyango lobushushu.

[2] Intsimbi yeepleyiti zeenqanawa ezinoxinzelelo oluphezulu.

Kwishishini le-petrochemical, i-gasification yamalahle, amandla enyukliya kunye nezikhululo zamandla, iipleyiti zentsimbi eziphantsi kwe-alloy-resistant zisetyenziswa ngokubanzi ukwenza iinqanawa zoxinzelelo. Iimpawu eziphambili eChina ziyi-15CrMoG iipayipi ze-alloy eziphezulu zoxinzelelo (1.25Cr-O.5Mo), 12Cr2Mo (2.25Cr-1Mo) kunye ne-12Cr1MoV, njl njl. Umzekelo, i-hot-wall hydrogenation reactors isebenzisa kakhulu i-2.25Cr-1Mo) (25-150mm). ), ngenxa yokuba izixhobo zisebenza phantsi kweemeko zokushisa okuphezulu, uxinzelelo oluphezulu kunye nokuxhatshazwa kwe-hydrogen ixesha elide, ngelixa liqwalasela ukuthintela ukukhutshwa kwe-embrittlement kwi-475 ° C, izinto ezifunekayo ukuba zibe nokucoceka okuphezulu, kunye nesulfure kunye ne-phosphorus. kulindeleke ukuba zibe ngaphantsi kwe-0.01% kunye ne-tin ephantsi kakhulu, Izinto ezinobungozi ezifana ne-antimony kunye ne-arsenic zifuna ukunyibilikiswa kwesithando sombane kunye nokucocwa kwangaphandle.

[3]Intsimbi yeziqhoboshi.

Intsimbi ye-Fastener yinto ephambili edlala indima ekudityanisweni kwee-injini ze-steam, ii-boilers kunye nezinye izixhobo ze-container-high-pressure. Ifuna umda owaneleyo wesivuno, uzinzo oluphezulu lokuphumla, iplastiki elungileyo ehlala ixesha elide kunye nobuntununtunu benotshi encinci yexesha elide. Ukumelana ne-oxidation kunye nokusebenza kakuhle kokusika. Iimpawu eziphambili eChina ziyi-25Cr2Mo, 25Cr2MoV, 25Cr2Mo1V, 20Cr1M01VNbTiB, njl., ezinokusetyenziswa kuluhlu lwe-500~570℃ ngokulandelanayo. La mabakala asetyenziswa ngokubanzi emva kokucima kunye nokuqunjelwa.

[4] Intsimbi ye-rotor (i-spindle, impeller).

Eyona shaft, i-impeller kunye ne-integrated forged rotor yenye yezinto eziphambili ze-injini yomphunga. Isixhobo siyafuneka ukuba sibe neepropathi ezilungileyo ezibanzi zoomatshini, ukuqina kokwaphuka, ukuxhathisa okuphezulu kokunyuka kunye namandla okunyamezela, kunye nokumelana nokudinwa kwe-thermal. Iimpawu ezisetyenziswa ngokuqhelekileyo ze-spindle kunye ne-impeller e-China yi-35CrMo, i-35CrMoV, i-27Cr2Mo1V, i-12Cr3MoWV, njl njl. I-rotor ye-gas turbine yenziwe ngentsimbi ye-20Cr3MoWV. Ukusebenzisa ukucima kunye nonyango lokufudumala. Kwimibhobho emikhulu efana ne-rotors eyenziweyo kunye ne-impellers, ukuze kunyibilike ngokupheleleyo i-vanadium carbide kunye nokuphucula iplastiki kunye nokuqina, ukunyangwa kwangaphambili okuqhelekileyo kunokwenziwa ngaphambi kokucinywa, okanye inkqubo yonyango lobushushu lwesibini esiqhelekileyo kunye nobushushu singasetyenziswa.

[5] I-1Cr5Mo kunye ne-Cr6SiMo yentsimbi.

Ezi zigaba zimbini zinezona zinto ziphezulu zokudibanisa kwintsimbi ye-pearlitic enganyangeki ukushisa. Banokumelana nobushushu obuhle kunye nokunganyangeki kwe-corrosion kwimidiya ye-petroleum. Zisetyenziswa ngokubanzi ekwenzeni imibhobho kunye neenqanawa zepetroleum distillation izixhobo, ukufudumeza iityhubhu zesithando somlilo kunye noTshintshiselwano lobushushu, njl. njl., Zikwasetyenziswa njengokufa kwesitampu esitshisayo, iimpompo zamafutha, iivalvu, izixhoma kwibhoyila kunye nezinye iindawo. Ngokuqhelekileyo ubushushu bokusetyenziswa bungaphantsi kwama-650 ℃. Ekubeni le ntsimbi iyintsimbi eqinile yomoya, i-weld seam inobunzima obuphezulu kunye neplastiki engafanelekanga, ngoko kufuneka ipholiswe kancinane kwaye ifakwe emva kwe-welding.

Ukuqengqeleka okushushu (ityhubhu yentsimbi ekhutshiweyo engenamthungo): ityhubhu engqukuva → ukufudumeza → ukugqobhoza → ukuqengqeleka okuqengqelekayo okuthathu, ukuqengqeleka okuqhubekayo okanye ukukhutshwa → ukususwa kwetyhubhu → ukulinganisa (okanye ukunciphisa) → ukupholisa → ityhubhu yebhiliti → ukolula → Uvavanyo loxinzelelo lwamanzi (okanye isiphene ubhaqo) → phawula → ugcino.

Umbhobho wentsimbi obandayo ozotyiweyo (oqengqiwe): umbhobho wetyhubhu engqukuva → ukufudumeza → ukugqobhoza → isihloko → ukuqhola → ukuchola → ukuthambisa (iplate yobhedu) → umzobo obandayo ogqithisayo (ukuqengqeleka okubandayo) → ityhubhu yebillet → unyango lobushushu → ukolula → Uvavanyo loxinzelelo lwamanzi (ukubona iziphene) → phawula → ugcino.

I-GB/T8162-2008 (ipayipi yensimbi engenamthungo yesakhiwo). Ikakhulu isetyenziselwa isakhiwo esiqhelekileyo kunye nesakhiwo soomatshini. Izinto zayo ezimele (iimpawu): i-carbon steel 20, i-45 insimbi; intsimbi ye-alloy Q345, 20Cr, 40Cr, 20CrMo, 30-35CrMo, 42CrMo, njl.

I-GB/T8163-2008 (ipayipi yentsimbi engenamthungo yokuhambisa ulwelo). Isetyenziswa kakhulu kubunjineli kunye nezixhobo ezinkulu zokuthutha imibhobho yamanzi. Izinto ezimele (i-brand) yi-20, i-Q345, njl.

I-GB3087-2008 (Iibhubhu zentsimbi ezingenamthungo kwiibhoyili eziphantsi kunye neziphakathi). Isetyenziswa ikakhulu kwiibhoyila zemizi-mveliso kunye neebhoyila zasekhaya ukuthutha imibhobho yamanzi yoxinzelelo oluphantsi naphakathi. Izinto ezimeleyo ziyi-10 kunye ne-20 yentsimbi.

I-GB5310-2008 (Iibhubhu zentsimbi ezingenamthungo kwiibhoyili zoxinzelelo oluphezulu). Ikakhulu isetyenziselwa ubushushu obuphezulu kunye noxinzelelo oluphezulu oluhambisa iiheader zolwelo kunye nemibhobho kwiibhoyila kwizikhululo zamandla kunye nezixhobo zamandla enyukliya. Izinto ezimele i-20G, i-12Cr1MoVG, i-15CrMoG, njl.

I-GB5312-1999 (i-Carbon steel kunye ne-carbon-manganese steel seamless pipe imibhobho yeenqanawa). Isetyenziswa kakhulu kwimibhobho ye-I kunye ne-II yoxinzelelo kwiibhoyila zaselwandle kunye ne-superheaters. Izinto ezimeleyo ziyi-360, 410, 460 amabakala ensimbi, njl.

I-GB6479-2000 (Iibhobho zentsimbi ezingenamthungo zezixhobo zesichumisi soxinzelelo oluphezulu). Isetyenziswa kakhulu ukuhambisa ubushushu obuphezulu kunye nemibhobho yoxinzelelo oluphezulu yolwelo kwizixhobo zesichumiso. Izinto ezimele i-20, i-16Mn, i-12CrMo, i-12Cr2Mo, njl.

I-GB9948-2006 (Ipayipi yensimbi engenamthungo yokuqhekeka kwepetroleum). Isetyenziswa kakhulu kwiibhoyila, izitshintshi zobushushu kunye nemibhobho yamanzi ye-petroleum smelters. Izinto zayo ezimele ziyi-20, 12CrMo, 1Cr5Mo, 1Cr19Ni11Nb, njl.

I-GB18248-2000 (Iibhubhu zentsimbi ezingenamthungo kwiisilinda zegesi). Isetyenziswa kakhulu ukwenza iisilinda ezahlukeneyo zegesi kunye nehydraulic. Izinto zayo ezimele ziyi-37Mn, 34Mn2V, 35CrMo, njl.

I-GB/T17396-1998 (Imibhobho yentsimbi engenamthungo eqengqelekayo eshushu yeepropu zehydraulic). Isetyenziswa kakhulu ukwenza izixhaso ze-hydraulic emgodini wamalahle, iisilinda kunye neentsika, kunye nezinye iisilinda zehydraulic kunye neentsika. Izinto zayo ezimele ziyi-20, 45, 27SiMn njalo njalo.

I-GB3093-1986 (Imibhobho yentsimbi engenamthungo ephezulu yoxinzelelo lweenjini zedizili). Isetyenziswa kakhulu kumbhobho weoyile woxinzelelo oluphezulu lwenkqubo yokutofa kwe-injini ye-diesel. Umbhobho wensimbi ngokuqhelekileyo utsalwa ngokubanda, kwaye izinto ezimeleyo ziyi-20A.

I-GB/T3639-1983 (umbhobho wentsimbi ongenamthungo owenziweyo obandayo okanye ogqitywe ngokuchanileyo). Isetyenziselwa ikakhulu kwimibhobho yentsimbi esetyenziswa kwizakhiwo zoomatshini kunye nezixhobo zoxinzelelo lwekhabhoni ezifuna ukuchaneka komgangatho ophezulu kunye nokugqiba kakuhle komhlaba. Izinto zayo ezimele ziyi-20, i-45 yensimbi, njl.

I-GB/T3094-1986 (umbhobho wentsimbi ongenamthungo otsaliweyo obandayo owenziwe ngentsimbi). Ikakhulu isetyenziselwa ukwenza iinxalenye ezahlukeneyo zesakhiwo kunye neenxalenye, kwaye izinto zayo zikumgangatho ophezulu wekhabhoni yesakhiwo sentsimbi kunye nentsimbi ephantsi ye-alloy.

I-GB/T8713-1988 (Ukuchaneka kwangaphakathi kombhobho wentsimbi ongenamthungo wangaphakathi we-hydraulic kunye ne-pneumatic cylinders). Ikakhulu isetyenziselwa ukwenza imibhobho yentsimbi epholileyo ezotyiweyo okanye ebandayo esongiweyo enedayamitha echanekileyo yangaphakathi yeesilinda zehydraulic kunye nepneumatic. Izinto zayo ezimele ziyi-20, i-45 yensimbi, njl.

I-GB13296-1991 (Iibhubhu zetsimbi ezingenasici ezingenamthungo kwiibhoyili kunye nokutshintsha ubushushu). Isetyenziswa kakhulu kwiibhoyila, ii-superheaters, i-heat exchangers, i-condensers, i-catalytic tubes, njl. Isetyenziselwe ubushushu obuphezulu, uxinzelelo oluphezulu, imibhobho yentsimbi enganyangekiyo kwi-corrosion. Izixhobo zayo ezimele ziyi-0Cr18Ni9, 1Cr18Ni9Ti, 0Cr18Ni12Mo2Ti, njl.

I-GB/T14975-1994 (Intsimbi engenamthungo yombhobho yentsimbi yesakhiwo). Isetyenziselwa ikakhulu kwisakhiwo esiqhelekileyo (ihotele kunye nomhombiso wokutyela) kunye nesakhiwo somatshini samashishini ekhemikhali, axhathisayo kwi-atmospheric and acid corrosion kwaye anamandla athile emibhobho yentsimbi. Izixhobo zayo ezimele ziyi-0-3Cr13, 0Cr18Ni9, 1Cr18Ni9Ti, 0Cr18Ni12Mo2Ti, njl.

I-GB/T14976-1994 (Insimbi engenamthungo umbhobho wentsimbi yokuthuthwa kwamanzi). Isetyenziswa kakhulu kwimibhobho ethutha imidiya eyonakalisayo. Izinto ezimeleyo zi-0Cr13, 0Cr18Ni9, 1Cr18Ni9Ti, 0Cr17Ni12Mo2, 0Cr18Ni12Mo2Ti, njl.

YB/T5035-1993 (Imibhobho yentsimbi engenamthungo yee-axle casings zemoto). Ikakhulu isetyenziselwa ukwenza umgangatho ophezulu wekhabhoni yentsimbi kunye nentsimbi yolwakhiwo lwentsimbi eshushu eqengqelekayo eqengqelekayo imibhobho yentsimbi engenamthungo yemoto enemikhono enesiqingatha se-asi kunye nokuqhuba iityhubhu ze-axle. Izinto zayo ezimele ziyi-45, 45Mn2, 40Cr, 20CrNi3A, njl.

I-API SPEC5CT-1999 (i-Casing and Tubing Specification), iqulunqwe kwaye ikhutshwe yi-American Petroleum Institute (i-American Petreleum Instiute, ebizwa ngokuba yi "API") kwaye isetyenziswe kuzo zonke iindawo zehlabathi. Phakathi kwazo: I-Casing: umbhobho ophuma kumphezulu womhlaba ukuya equleni kwaye usebenza njengelinen eludongeni lomthombo. Imibhobho idityaniswe ngokudibanisa. Izinto eziphambili ziyimigangatho yensimbi efana ne-J55, i-N80, kunye ne-P110, kunye namabakala ensimbi afana ne-C90 kunye ne-T95 echasene ne-hydrogen sulfide corrosion. Intsimbi yayo ephantsi (J55, N80) inokudityaniswa nombhobho wentsimbi. Iityhubhu: Umbhobho ofakwe kwisingxobo ukusuka kumhlaba ukuya kumaleko we-oyile. Imibhobho idibaniswe ngokudibanisa okanye ngokudibeneyo. Indima yeyunithi yokupompa kukuthutha ioli ukusuka kwinqanaba leoli ukuya emhlabeni ngombhobho weoyile. Izinto eziphambili ziyi-J55, i-N80, i-P110, kunye ne-C90, echasene ne-hydrogen sulfide corrosion, ehlanganiswe kwaye ikhutshwe yi-American Petroleum Institute, kwaye isetyenziswa kwihlabathi jikelele.