I-P91 i-Solid Alloy Tube

P91 ingxubevange umbhobho ngokwe GB/T8162-87

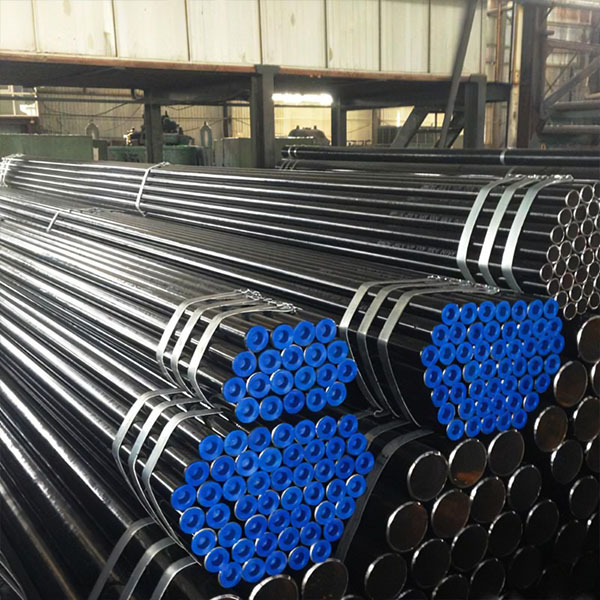

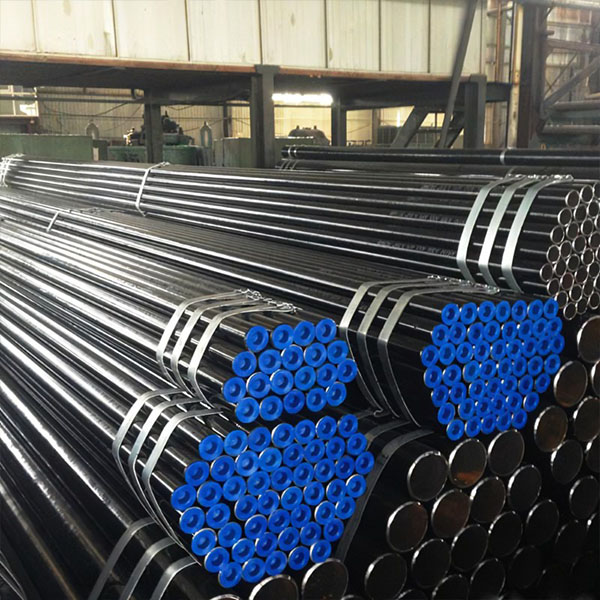

4.1.Iinkcukacha: Idayamitha yangaphandle yetyhubhu eqengqelekayo yi-32~630mm.Ubukhulu bodonga yi-2.5 ~ 75mm.Idayamitha engaphandle yombhobho oqengqelekayo (obandayo otsalweyo) yi-5~200mm.Ubukhulu bodonga buyi-2.5-12mm.

4.2.Umgangatho wokubonakala: indawo yangaphakathi nangaphandle yombhobho wentsimbi akufunekanga ibe neentanda, ukugotywa, imiqulu, i-delamination, imigca yeenwele kunye neziphene zokonakala.Ezi ziphene kufuneka zisuswe ngokupheleleyo, kwaye ubukhulu bodonga kunye nobubanzi bangaphandle akufanele budlule ukutenxa okungalunganga emva kokususwa.

Indlela yokuvelisa

Ngokweendlela ezahlukeneyo zokuvelisa, inokuthi ihlulwe ibe yimibhobho eshushu, iityhubhu ezipholileyo, iityhubhu ezikhutshiweyo, njl njl.

1.1.Iityhubhu ezishushu eziqengqelekayo ze-P91 ze-alloy ziveliswa ngokubanzi kwi-automatic rolling mill.I-tube eqinile ihlolwe kwaye ihlanjululwe iziphene zomhlaba, inqunyulwe ubude obufunekayo, igxininise ekupheleni kombhobho, ize ithunyelwe kwisithando somlilo ukuze sitshiswe kwaye sihlatywe kumatshini wokubhoboza.Xa i-perforation iqhubeka ijikeleza kwaye iqhubela phambili ngexesha elifanayo, phantsi kwesenzo se-roller kunye neplagi, i-cavity yenziwa ngokuthe ngcembe ngaphakathi kwi-tube blank, ebizwa ngokuba yi-capillary tube.Kwaye emva koko ithunyelwe kwi-auto rolling mill ukuqhubeka nokuqengqeleka.Okokugqibela, ubukhulu bodonga lonke bufaniswe ngumatshini wokulinganisa, kwaye ububanzi bulinganiswa ngomatshini wokulinganisa ukuhlangabezana neemfuno ezibaluliweyo.Yindlela ephucuke ngakumbi yokuvelisa imibhobho yengxubevange ye-P91 eshushu eqengqelekayo kusetyenziswa amatye okusila aqengqelekayo.

1.2.Ukuba ufuna ukufumana imibhobho engenamthungo enobukhulu obuncinci kunye nomgangatho ongcono, ukuqengqeleka okubandayo, umzobo obandayo, okanye indibaniselwano yeendlela ezimbini kufuneka isetyenziswe.I-Cold rolling idla ngokuqhutyelwa kwi-rolling mill emibini ephezulu.Umbhobho wensimbi ugqitywe kwi-annular pass eyenziwe yi-variable cross-section circular hole groove kunye neplagi ye-tapered stationary.Umzobo obandayo udla ngokuqhutyelwa kwi-chain-chain okanye i-double-chain ebandayo umatshini wokudweba we-0.5 ukuya kwi-100T.

1.3.Indlela ye-extrusion kukubeka i-tube efudumeleyo engenanto kwi-cylinder ye-extrusion evaliweyo, kwaye intonga ene-perforated kunye nentonga ye-extrusion ihamba kunye ukuze ikhuphe inxalenye ekhutshiweyo ukusuka kumngxuma wokufa omncinci.Le ndlela inokuvelisa iibhobho zetsimbi ezinamadamitha amancinci.

2.1.ityhubhu ye-P91 ye-alloy inoluhlu olubanzi lokusetyenziswa.Umbhobho we-P91 we-alloy wenjongo ngokubanzi ugqitywe kwintsimbi ye-carbon structural steel, i-low-alloy structural steel okanye i-alloy structural steel, kwaye inemveliso enkulu.Isetyenziswa ikakhulu njengemibhobho okanye iinxalenye zesakhiwo sokuhambisa ulwelo.

2.2.Ngokweenjongo ezahlukeneyo, yahlulwe yaba ziindidi ezintathu zobonelelo: a.Ngokokwakheka kweekhemikhali kunye neempawu zoomatshini;b.Ngokweempawu zoomatshini;c.Ngokovavanyo lwe-hydraulic.Imibhobho yentsimbi ebonelelwe ngokweendidi u-a no-b, ukuba isetyenziselwa ukumelana noxinzelelo lolwelo, nayo iya kufakwa kuvavanyo lwehydraulic.

2.3.Imibhobho ye-P91 yealloy ngeenjongo ezikhethekileyo ibandakanya imibhobho ye-P91 yealloy yeebhoyila, i-P91 yealloy pipes ye-geology kunye nemibhobho engenamthungo yepetroleum.

Izinto eziphambili zokuxutywa kwemibhobho ye-alloy yi-silicon, i-manganese, i-chromium, i-nickel, i-molybdenum, i-tungsten, i-vanadium, i-titanium, i-niobium, i-zirconium, i-cobalt, i-aluminiyam, ubhedu, i-boron, umhlaba onqabileyo, njl njl. Inani elincinci lezinto eziyimfuneko Ukongeza ekuphepheni i-silicon, i-manganese, i-phosphorus, kunye nesulfure, ikwaqulethe umlinganiselo othile wezinto ezixutywayo. , ilothe, umhlaba onqabileyo, njl njl. Enye okanye iintlobo ezininzi zentsimbi zibizwa ngokuba yi-alloy steels.Iinkqubo zensimbi ye-alloy ziyahluka kunye neemeko zabo zobutyebi, iimeko zokuvelisa kunye nokusetyenziswa.Ngaphambili, iinkqubo ze-nickel kunye nentsimbi ziye zaphuhliswa kumazwe angaphandle.I-China iye yafumanisa ukuba i-silicon, i-manganese, i-Vanadium, i-titanium, i-niobium, i-boron, i-load, kunye ne-rare earth alloy steel system i-alloy steel akhawunti malunga neshumi lepesenti yemveliso yentsimbi.Ngokuqhelekileyo, imibhobho yensimbi ye-alloy inokwahlulwa ibe ziindidi ezi-8 ezinkulu ngokusetyenziswa kwazo.Iindidi, zezi: imibhobho yentsimbi yolwakhiwo lwealloyi, imibhobho yentsimbi yasentwasahlobo, imibhobho yentsimbi ethweleyo, imibhobho yentsimbi yesixhobo sealloyi, imibhobho yensimbi enesantya esiphezulu, imibhobho yentsimbi, imibhobho yentsimbi ekwaziyo ukumelana nobushushu, imibhobho yentsimbi yombane yesilicon PC/ABS. zinokwakheka kakuhle kwaye zinokucutshungulwa kwiimoto ezinkulu Izixhobo, ezinje ngeefenda zemoto, zinexabiso eliphezulu lokusebenza.Imibhobho yentsimbi ye-alloy yenziwe ngentsimbi yekhabhoni eqhelekileyo ngokongeza inani elifanelekileyo lezinto ezixubeneyo enye okanye ngaphezulu kulwahlulo lwemibhobho yentsimbi ye-iron-carbon alloy: imibhobho yentsimbi yahlulwe yaba yimibhobho ye-P91 yealloy kunye ne-welding Steel imibhobho njalo njalo.