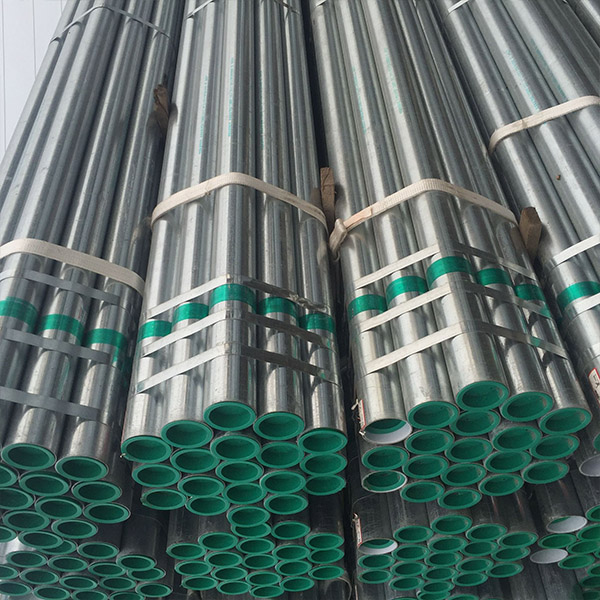

Dip eshushu intsimbi

Ubukhulu bodonga lwegama (mm): 2.0, 2.5, 2.8, 3.2, 3.5, 3.8, 4.0, 4.5.

Imilinganiselo yomlinganiso (c): 1.064, 1.051, 1.045, 1.040, 1.036, 1.034, 1.032, 1.028.

Qaphela: Iimpawu ze-mechanical zetsimbi ziyisalathisi esibalulekileyo sokuqinisekisa ukusebenza kokugqibela kokusetyenziswa (iipropati zomatshini) zetsimbi, kwaye kuxhomekeke kwimichiza yentsimbi kunye nenkqubo yokunyanga ukushisa. Kwinqanaba lombhobho wensimbi, ngokweemfuno ezahlukeneyo zesicelo, iimpawu zokuqina (amandla okuqina, amandla okuvelisa okanye isivuno, ukunyusa),ukuqina kunye nezalathisi zokuqina zichaziwe, kunye neempawu zobushushu eziphakamileyo nezisezantsi ezifunwa ngabasebenzisi.

Amabanga entsimbi: Q215A; Q215B; Q235A; Q235B.

Ixabiso loxinzelelo lovavanyo / iMpa: D10.2-168.3mm yi-3Mpa; I-D177.8-323.9mm yi-5Mpa

Imigangatho yesizwe kunye nemigangatho yobungakanani bemibhobho yegalvanized

I-GB/T3091-2015 Umbhobho wentsimbi odityanisiweyo wokuthutha ulwelo oluphantsi koxinzelelo

I-GB/T13793-2016 Umbhobho wentsimbi owenziwe ngombane omde

I-GB/T21835-2008 ubungakanani bombhobho wentsimbi obudityanisiweyo kunye nobunzima beyunithi

Inkqubo yokuhamba yile:ityhubhu emnyama yokuvasa-amanzi okuhlamba-pickling-amanzi ukuhlamba-ukumanzisa-ukumanzisa-ashushu dip galvanizing-ukuvuthela-yangaphakathi ukuvuthela-moya-ukupholisa-amanzi okupholisa -Passivation-amanzi ukuhlamba-ukuhlola-isisindo-ukugcinwa.

Imibhobho edla ngokubizwa ngokuba yizinki, imibhobho enezinki isetyenziselwa irhasi, kunye nohlobo lwemibhobho yentsimbi esetyenziselwa ukufudumeza ikwayimibhobho enamazinki. Imibhobho eyenziwe ngegalvanized isetyenziswa njengemibhobho yamanzi. Emva kweminyaka emininzi yokusetyenziswa, i-rust eninzi kunye nokungcola kuveliswa kwimibhobho, kwaye amanzi aphuzi aphuma ngaphandle nje angcolise i-sanitary ware, kwaye ixutywe kunye neebhaktheriya ezizala kudonga lwangaphakathi olungalinganiyo, kwaye i-corrosion ibangela. isiqulatho esiphakamileyo sesinyithi esinzima emanzini, esibeka emngciphekweni impilo yomzimba womntu.

Indlela yokudibanisa umbhobho wentsimbi yesinyithi: i-threaded, i-welded.

Umdibaniso we-groove

(1) Ukuqhekeka kwe-weld ye-roll groove

1. Lungisa iimbambo ze-welding eludongeni lwangaphakathi lwe-groove ye-pressure groove inxalenye ye-nozzle ukunciphisa ukuxhathisa kwe-rolling groove.

I-2, Lungisa i-axis yombhobho wensimbi kunye nezixhobo zokugoba, kwaye zifuna umbhobho wensimbi kunye nezixhobo zokugoba ukuba zibe kwinqanaba.

3. Lungisa isantya sokucinezela i-groove, kwaye i-groove yokwenza ixesha ayinakudlula i-stipulation, sebenzisa amandla ngokulinganayo kwaye ngokuthe ngcembe.

(2) Ukuqhekeka kombhobho wentsimbi ye-groove

1. Lungisa iimbambo ze-welding eludongeni lwangaphakathi lwenxalenye yoxinzelelo lwe-groove yomlomo wombhobho ukunciphisa ukuxhathisa kwe-rolling groove.

I-2, Lungisa i-axis yombhobho wensimbi kunye nezixhobo zokugoba, ezifuna ukuba umbhobho wensimbi kunye nezixhobo zokugoba zibe kwinqanaba.

3. Lungisa isantya sokucofa, isantya esicinezelayo asikwazi ukudlula ummiselo, sebenzisa amandla ngokulinganayo nangokucotha.

4. Khangela ububanzi kunye nemodeli ye-roller yokuxhasa kunye ne-pressure roller ye-rolling groove isixhobo, kwaye ukhangele ukuba kukho ukungahambi kakuhle kwisayizi yee-roller ezimbini, ezinokubangela ukubanjwa.

5. Sebenzisa i-vernier caliper ukujonga ukuba i-groove yombhobho wensimbi icacisiwe.

(3) I-groove eyenziwe ngumatshini we-rolling groove kufuneka ihlangabezane nezi mfuno zilandelayo

I-1, Umphezulu wokuphela kombhobho ukuya kwinqanaba le-groove kufuneka lihambe kakuhle kwaye lingabikho ukungalingani kunye namanqaku e-roll.

I-2, Umbindi we-groove kufuneka ugxininise kunye nodonga lombhobho, ububanzi kunye nobunzulu be-groove kufuneka buhlangabezane neemfuno, kwaye ukhangele ukuba uhlobo lwe-clamp luchanekile.

3. Faka i-lubricant kwiringi yokutywina yerabha kwaye ujonge ukuba iringi yokutywina yerabha yonakele na. Isithambiso akufuneki sibe sisithambiso se-oyile.

Uqhagamshelo oludityanisiweyo

1. Umlomo wombhobho wombhobho wensimbi yensimbi awukho kumgca ochanekileyo kwaye kukho ingxaki yomlomo we-oblique wepayipi yensimbi emva kokuqhawula. Kunconywa ukunqumla intloko yombhobho ixesha elifutshane ngaphambi kokuba kuqhutywe.

I-2, Emva kokuba i-galvanized steel pipe nozzles ixhunyiwe, i-nozzles ezimbini azixhunyiwe ngokuqinileyo, okubangelwa ubuninzi obungalinganiyo bombhobho odibeneyo; kwaye umbhobho u-elliptical ngenxa yezizathu zayo okanye i-bumps yokuthutha. Kunconywa ukunqumla intloko yombhobho ixesha elifutshane. Inkqubo kwakhona.

3. Emva kokuba imibhobho yemibhobho yentsimbi ikhutshiwe, amadyungudyungu avela kwimibhobho:

4. Ngenxa yezizathu zobugcisa ngexesha le-welding.

5. Kukho i-zinc nodules kwi-nozzle, enokubangela ubunzima be-welding kunye ne-blisters. Ukuba i-zinc nodules inkulu kakhulu kwaye ininzi imibhobho, i-zinc nodules elula kufuneka isuswe.

Uqhagamshelo ngocingo

I-1, iqhosha elinemisonto: Ihupu yombhobho kunye nentambo enemisonto ayinakuqhagamshelwa ngokupheleleyo, ikhulule, inqumle inxalenye yebhanti engaqhelekanga, kwaye uphinde ufake umsonto.

2. Intambo yombhobho wensimbi kunye nentambo ye-hoop yepayipi ayifani kwaye ayikwazi ukudibaniswa. I-hoop yombhobho kufuneka itshintshwe okanye isixhobo kufuneka sihlengahlengiswe kwaye siphinde sifakwe umsonto.

3. Ushicilelo olulahlekileyo emva kokuba umbhobho wentsimbi uphothiwe: Linganisa ukuba ubukhulu bodonga lombhobho wentsimbi bungahlangabezana neemfuno zobukhulu bomgangatho wombhobho ophothiweyo.