Umbhobho oGqwethiweyo

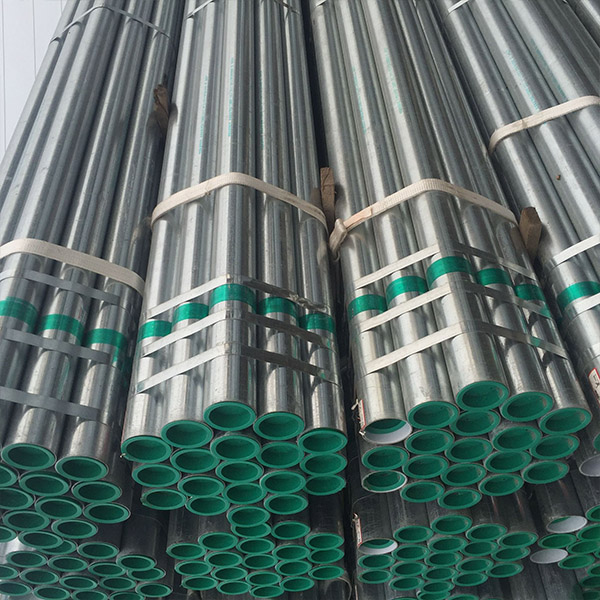

Inkqubo yokuhamba yile:ityhubhu emnyama ukuhlamba-amanzi ukuhlamba-pickling-amanzi ukuhlanjululwa-ukumanzisa-ukumanzisa-ashushu dip galvanizing-ukuvuthela-yangaphakathi ukuvuthela-moya-ukupholisa-amanzi okupholisa -Passivation-amanzi ukuhlamba-ukuhlola-isisindo-ukugcinwa.

I-1, i-Brand kunye ne-chemical composition

Ibakala kunye nokwakhiwa kweekhemikhali zetsimbi yeepayipi zensimbi ezinobumba kufuneka zihambelane nebakala kunye nokwakheka kweekhemikhali zetsimbi kwimibhobho emnyama njengoko kuchazwe kwi-GB / T3091.

2, Indlela yokuvelisa

Indlela yokuvelisa umbhobho omnyama (i-furnace welding okanye i-welding yombane) ikhethwe ngumenzi.I-Hot-dip galvanizing isetyenziselwa ukwenza igalvanizing.

3. Umsonto kunye nombhobho odibeneyo

(a) Kwimibhobho yentsimbi enesitayile ehanjiswa ngeentambo, iintambo kufuneka zenziwe ngoomatshini emva kokufakwa kwegalvanizing.Intambo kufuneka ihambelane nemigaqo ye-YB 822.

(b) Amalungu emibhobho yentsimbi kufuneka ahambelane neYB 238;izidibanisi zemibhobho yentsimbi ethambileyo kufuneka zihambelane neYB 230.

4. Iimpawu zoomatshini Iipropathi zomatshini wemibhobho yentsimbi ngaphambi kokuba i-galvanizing kufuneka ihlangabezane neemfuno ze-GB 3091.

5. Ukufana komgangatho wegalvanized Umbhobho wentsimbi ekhandiweyo kufuneka uvavanywe ukufana komgangatho we-galvanized layer.Isampuli yombhobho yensimbi ayiyi kujika ebomvu (i-copper-plated) emva kokuntywiliselwa kwisisombululo sobhedu se-sulfate ngamaxesha angama-5 alandelelanayo.

I-6, uvavanyo lwe-gold bend ebandayo yentsimbi yombhobho kunye ne-diameter ye-nominal engekho ngaphezu kwe-50mm kufuneka ibe luvavanyo lokugoba olubandayo.I-angle yokugoba yi-90 °, kwaye i-radius yokugoba ngamaxesha angama-8 ububanzi bangaphandle.Akukho nto yokuzalisa ngexesha lovavanyo, kwaye i-weld yesampuli kufuneka ibekwe ngaphandle okanye inxalenye ephezulu yendlela yokugoba.Emva kovavanyo, akufuneki kubekho iintanda kunye ne-peeling ye-zinc layer kwisampuli.

I-7, Uvavanyo loxinzelelo lwamanzi Uvavanyo loxinzelelo lwamanzi kufuneka lwenziwe kwi-clarinet, kwaye uvavanyo lwangoku lwe-eddy lunokusetyenziswa endaweni yovavanyo loxinzelelo lwamanzi.Uxinzelelo lovavanyo okanye ubungakanani besampulu yokuthelekisa uvavanyo lwangoku lwe-eddy luya kuhlangabezana neemfuno ze-GB 3092. Iimpawu zomatshini zentsimbi zizibonakaliso ezibalulekileyo zokuqinisekisa ukusebenza kokugqibela kokusetyenziswa (iipropati zomatshini) zetsimbi.

① Amandla okuqina (σb):Amandla aphezulu (Fb) ukuba isampuli ithwala xa iphula ngexesha lenkqubo yokwelula, ihlulwe luxinzelelo (σ) olufunyenwe ngokwahlula indawo yokuqala ye-cross-sectional (So) yesampuli, ibizwa ngokuba yi-resistance Tensile strength (σb) , iyunithi yi-N/mm2 (MPa).Imele amandla aphezulu ezinto zetsimbi ukuxhathisa umonakalo phantsi kwamandla obunzima.Kwifomula: Fb-amandla aphezulu ukuba isampuli ithwala xa iphukile, N (Newton);Ke-indawo yokuqala yecandelo lomnqamlezo wesampulu, mm2.

②Inqaku lemveliso (σs):Kwizinto zetsimbi kunye nesiganeko sokuvunwa, uxinzelelo apho isampuli inokuqhubeka nobude ngaphandle kokunyusa amandla ngexesha lenkqubo yokwelula ibizwa ngokuba yindawo yesivuno.Ukuba amandla ehla, amanqaku aphezulu kunye nasezantsi kufuneka ahlulwe.Iyunithi yenqaku lesivuno yi-N/mm2 (MPa).Inqaku leSivuno esiPhezulu (σsu): Uxinzelelo oluphezulu phambi kokuba i-specimen ivelise kwaye amandla ehla okokuqala;Inqaku leSivuno esisezantsi (σsl): Ubuncinci boxinzelelo kwinqanaba lesivuno xa isiphumo sokuqala esidlulayo singathathelwa ngqalelo.Apho: Fs--isivuno samandla (rhoqo) ngexesha lenkqubo yokuqina kwesampulu, N (Newton) Ngoko-indawo yokuqala yecandelo lomnqamlezo wesampulu, mm2.

③ Ubude emva kokwaphuka:(σ) Kuvavanyo lwe-tensile, ipesenti yobude bobude be-gauge eyandisiweyo emva kokuba isampulu yaphulwe ukuya kubude be-original gauge ibizwa ngokuba yi-elongation.Ichazwe ngu σ, iyunithi yi%.Kwifomula: L1-ubude be-gauge ye-specimen emva kokuphuka, kwi-mm;I-L0-ubude be-gauge yokuqala yomzekelo, kwi-mm.

④ Ukucuthwa kwendawo:(ψ) Kuvavanyo lwe-tensile, ipesenteji yokunciphisa ubuninzi bendawo enqamlezileyo kwi-diameter encitshisiweyo yesampuli emva kokuba isampuli iphulwe kwindawo yokuqala ye-cross-sectional ebizwa ngokuba kukunciphisa indawo.Icaciswe ngo-ψ, iyunithi yi-%.Kwifomula: S0-indawo yokuqala yecandelo lomnqamlezo wesampulu, mm2;I-S1-indawo encinci ye-cross-sectional in the diameter encitshisiweyo yesampuli emva kokuba iphukile, mm2.

⑤ Isalathiso sokuqina:Ukukwazi kwezixhobo zetsimbi ukuxhathisa ukunyanzeliswa kwezinto eziqinileyo kumphezulu kubizwa ngokuba lukhuni.Ngokweendlela ezahlukeneyo zovavanyo kunye nobubanzi besicelo, ubulukhuni bunokwahlulwa bubulukhuni beBrinell, ukuqina kweRockwell, ukuqina kweVickers, ukuqina konxweme, ubulukhuni obuncinci kunye nobunzima obuphezulu bobushushu.Kukho imibhobho emithathu esetyenziswa ngokuqhelekileyo: Brinell, Rockwell, kunye nokuqina kweVickers.

Ukuqina kweBrinell (HB):Sebenzisa ibhola yentsimbi okanye ibhola ye-carbide enesamente enedayamitha ethile ukuyicinezela kumphezulu wesampulu ngamandla ovavanyo achaziweyo (F), susa amandla ovavanyo emva kwexesha elichaziweyo lokubamba, kwaye ulinganise i-identation diameter kumphezulu we isampuli (L).Ixabiso lobulukhuni beBrinell yi-quotient efunyenwe ngokwahlula amandla ovavanyo ngomphezulu we-spherical surface of the indentation.Icaciswe kwi-HBS (ibhola yentsimbi), iyunithi yi-N/mm2 (MPa).