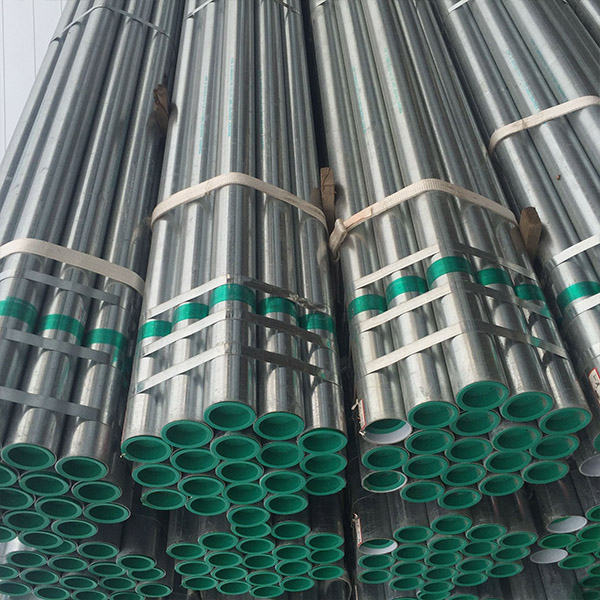

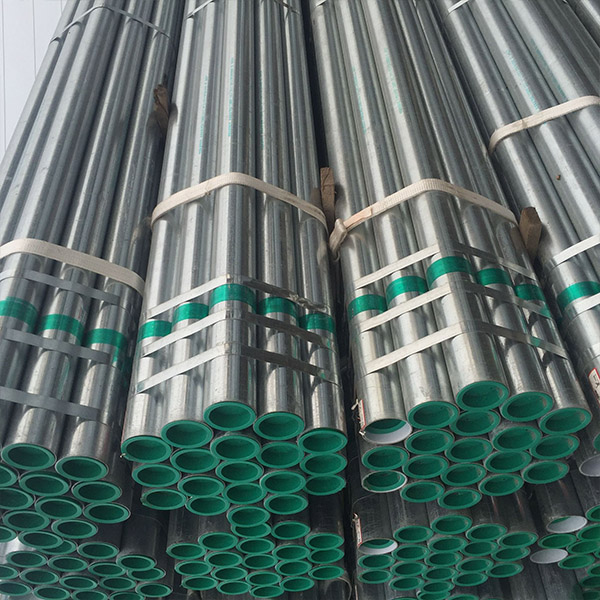

I-Hot-Dip Umbhobho weGalavanized

Umbhobho ofakwe igalvanized eshushu

Umbhobho owenziwe ngesinyithi oshushu-dip kukwenza ukuba isinyithi esinyibilikisiweyo siphendule kunye ne-matrix yentsimbi ukuvelisa umaleko we-alloy, ukwenzela ukuba i-matrix kunye ne-coating zidityaniswe. I-Hot-dip galvanizing kukuqala ukukha umbhobho wentsimbi. Ukuze kususwe i-iron oxide phezu kombhobho wentsimbi, emva kokuchola, icocwa kwitanki nge-ammonium chloride okanye i-zinc chloride isisombululo esinamanzi okanye isisombululo esixutywe ngamanzi se-ammonium chloride kunye ne-zinc chloride, kwaye emva koko ithunyelwe itanki yokubeka idiphu eshushu. I-Hot-dip galvanizing ineenzuzo zokugquma okufanayo, ukunamathela okuqinileyo kunye nobomi benkonzo ende. I-matrix yombhobho wensimbi owenziwe ngesinyithi oshushu-diphu ingena kwi-complex physical and chemical reaction kunye nesisombululo esityhidiweyo se-plating ukwenza umaleko we-alloy we-zinc-iron enganyangekiyo kunye nesakhiwo esihlangeneyo. Umaleko we-alloy udityaniswe kunye ne-zinc ecocekileyo kunye ne-matrix yombhobho wentsimbi, ngoko ukuxhathisa kwayo kunamandla.

Umbhobho obandayo wamazinki

Umbhobho we-galvanized obandayo u-electro-galvanizing, kwaye inani le-galvanizing lincinci kakhulu, kuphela i-10-50g / m2, kwaye ukuxhathisa kwayo kwe-corrosion kuhluke kakhulu kunombhobho we-galvanized dip. Abavelisi bemibhobho ye-galvanized ngokusesikweni, ukwenzela ukuba kuqinisekiswe umgangatho, uninzi lwabo alusebenzisi i-electro-galvanized (i-cold plating). Kuphela loo mashishini amancinci anezixhobo ezincinci kunye neziphelelwe lixesha asebenzisa i-electro-galvanization, kwaye ngokuqinisekileyo amaxabiso abo aphantsi kakhulu. UMphathiswa wezoKwakha ubhengeze ngokusemthethweni ukuba imibhobho ebandayo ene-galvanized technology ephelelwe lixesha kufuneka isuswe, kwaye imibhobho ebandayo efakwe igalvan ayivumelekanga ukuba isetyenziswe njengemibhobho yamanzi kunye negesi. Uluhlu lwezinki lombhobho wensimbi obandayo luyi-electroplated layer, kwaye i-zinc layer ihlukaniswe kwi-substrate yombhobho wensimbi. I-zinc layer incinci, kwaye i-zinc layer ibambelela nje kwisiseko sombhobho wensimbi kwaye iwela ngokulula. Ke ngoko, ukuxhathisa kwayo kukonakala. Kwizindlu ezisanda kwakhiwa, akuvumelekanga ukusebenzisa imibhobho yentsimbi ebandayo njengemibhobho yokuhambisa amanzi.

Ubukhulu bodonga lwegama (mm): 2.0, 2.5, 2.8, 3.2, 3.5, 3.8, 4.0, 4.5.

Imilinganiselo yomlinganiso (c): 1.064, 1.051, 1.045, 1.040, 1.036, 1.034, 1.032, 1.028.

Qaphela: Iimpawu ze-mechanical zetsimbi ziyisalathisi esibalulekileyo sokuqinisekisa ukusebenza kokugqibela kokusetyenziswa (iipropati zomatshini) zetsimbi, kwaye kuxhomekeke kwimichiza yentsimbi kunye nenkqubo yokunyanga ukushisa. Kwinqanaba lombhobho wensimbi, ngokweemfuno ezahlukeneyo zesicelo, iimpawu zokuqina (amandla okuqina, amandla okuvelisa okanye isivuno, ukunyusa), ukuqina kunye nokuqina kwezalathisi kucacisiwe, kunye neempawu zokushisa eziphezulu kunye eziphantsi ezifunwa ngabasebenzisi.

Amabanga entsimbi: Q215A; Q215B; Q235A; Q235B.

Ixabiso loxinzelelo lovavanyo / iMpa: D10.2-168.3mm yi-3Mpa; I-D177.8-323.9mm yi-5Mpa

Umgangatho wesizwe wangoku

Imigangatho yesizwe kunye nemigangatho yobungakanani bemibhobho yegalvanized

I-GB/T3091-2015 Umbhobho wentsimbi odityanisiweyo wokuthutha ulwelo oluphantsi koxinzelelo

I-GB/T13793-2016 Umbhobho wentsimbi owenziwe ngombane omde

I-GB/T21835-2008 ubungakanani bombhobho wentsimbi obudityanisiweyo kunye nobunzima beyunithi