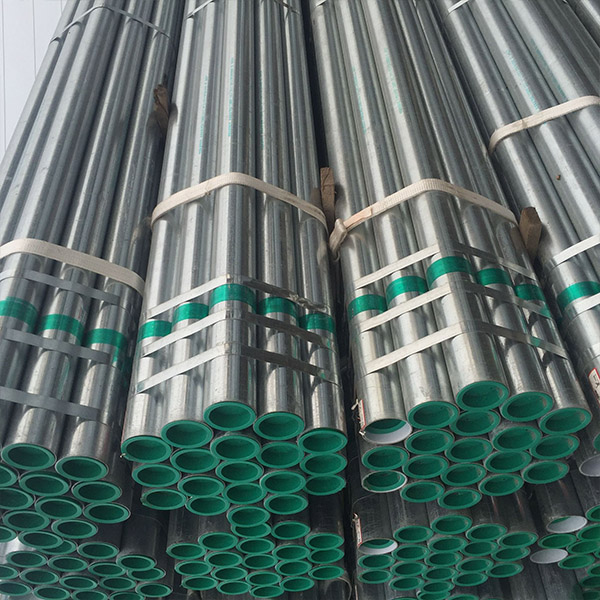

Umbhobho weNtsimbi obandayo, iHot-Dip yentsimbi

1. I-pre-galvanized: Umbhobho wentsimbi owenziwe ngaphambili ucutshungulwa ngokuthe ngqo kwi-hot-dip galvanized strip.

I-galvanized layer: 40-60g / sm, ukuba i-galvanized layer iyadingeka, inokucutshungulwa ngokomyalelo. (Ubukhulu yi 0.7mm-4.5mm)

2. Idiphu eshushu yediphu: Umbhobho wegalvanized wediphu unombhobho wezinki ojiyileyo kunombhobho owenziwe ngaphambili. Umbhobho wensimbi omnyama uya kubhaptizwa kwibhafu ye-zinc ukwenzela i-galvanizing. Ingubo ye-zinc ingaba: 200-500g / sm

Inkqubo yokuhamba yile:ityhubhu emnyama yokuvasa-amanzi okuhlamba-pickling-amanzi ukuhlamba-ukumanzisa-ukumanzisa-ashushu dip galvanizing-ukuvuthela-yangaphakathi ukuvuthela-moya-ukupholisa-amanzi okupholisa -Passivation-amanzi ukuhlamba-ukuhlola-isisindo-ukugcinwa.

1. Uphawu kunye nokwakheka kweekhemikhali

Ibakala kunye nokwakhiwa kweekhemikhali zentsimbi yeepayipi zensimbi eziphekiweyo kufuneka zihambelane nebakala kunye nokwakheka kweekhemikhali zentsimbi yeepayipi ezimnyama njengoko kuchazwe kwi-GB / T3091.

2. Indlela yokuvelisa

Indlela yokuvelisa umbhobho omnyama (i-furnace welding okanye i-welding yombane) ikhethwe ngumenzi. I-Hot-dip galvanizing isetyenziselwa ukwenza igalvanizing.

3. Umsonto kunye nokudibanisa umbhobho

(A) Kwimibhobho yensimbi enesitayile ehanjiswa ngeentambo, iintambo kufuneka zenziwe ngoomatshini emva kokufakwa kwe-galvanizing. Intambo kufuneka ihambelane nemigaqo ye-YB 822.

(B) Amalungu emibhobho yentsimbi kufuneka ahambelane neYB 238; izidibanisi zemibhobho yentsimbi ethambileyo kufuneka zihambelane neYB 230.

4. Iimpawu zoomatshini Iipropathi zomatshini wemibhobho yentsimbi ngaphambi kokuba i-galvanizing kufuneka ihlangabezane neemfuno ze-GB 3091.

5. Ukufana komgangatho we-galvanized layer Umbhobho wensimbi ovunyiweyo kufuneka uvavanywe ukufana komgangatho we-galvanized layer. Isampuli yepayipi yensimbi ayiyi kujika ebomvu (umbala wobhedu) emva kokuntywiliselwa kwisisombululo se-sulfate yethusi ngamaxesha angama-5 alandelelanayo.

6. Uvavanyo lokugoba olubandayo Umbhobho wensimbi owenziwe ngesinyithi kunye nobubanzi obungadluli kwi-50mm kufuneka ube phantsi kovavanyo lokugoba olubandayo. I-angle yokugoba yi-90 °, kwaye i-radius yokugoba ngamaxesha angama-8 ububanzi bangaphandle. Akukho nto yokuzalisa ngexesha lovavanyo, kwaye i-weld yesampuli kufuneka ibekwe ngaphandle okanye inxalenye ephezulu yendlela yokugoba. Emva kovavanyo, akufuneki kubekho iintanda kunye ne-peeling ye-zinc layer kwisampuli.

7. Uvavanyo loxinzelelo lwamanzi Uvavanyo loxinzelelo lwamanzi kufuneka lwenziwe kwi-clarinet. I-Eddy yangoku yokubona isiphene ingasetyenziswa endaweni yovavanyo loxinzelelo lwamanzi. Uxinzelelo lovavanyo okanye ubungakanani besampulu yokuthelekisa uvavanyo lwangoku lwe-eddy luya kuhlangabezana neemfuno ze-GB 3092. Iimpawu zomatshini zetsimbi ziyisalathisi esibalulekileyo sokuqinisekisa ukusebenza kokugqibela kokusetyenziswa (iipropati zomatshini) zentsimbi.

I-Shandong Jinbaicheng Metal Material Co., Ltd. ibekwe eShandong, eyona siseko semveliso yombhobho odityanisiweyo wehlabathi. Emva kweminyaka yokusebenza nzima, kuye kwasekwa indlela yophuhliso lotyalo-mali eyohlukeneyo. Ngokuhambelana neemfuno zeshishini elitsha, sinika umdlalo opheleleyo kwiinzuzo zethu ukuze sifezekise isikali, ulwakhiwo kunye nomgangatho. Uphuculo olubanzi lweenzuzo.

Sisebenza ngokukhethekileyo ekuthengiseni imibhobho yentsimbi, imibhobho yentsimbi eshushu, imibhobho engenamthungo,. Emva kweminyaka emininzi yophuhliso, siye saseka ixesha elide

Sebenzisana nabathengi abavela kumazwe angaphezu kwama-70 kwihlabathi liphela, kubandakanya iCanada, iOstreliya, iSingapore, iThailand, uMzantsi Korea, iVietnam, iMexico, iChile, iPeru kunye neNew Zealand. Imveliso yonyaka yi-700,000 yeetoni.

Indlela yokudibanisa umbhobho wentsimbi yesinyithi: i-threaded, i-welded.

Umdibaniso we-groove

(1) Ukuqhekeka kwe-weld ye-roll groove

1. Lungisa iimbambo ze-welding eludongeni lwangaphakathi lwe-groove ye-pressure groove inxalenye ye-nozzle ukunciphisa ukuxhathisa kwe-rolling groove.

I-2, Lungisa i-axis yombhobho wensimbi kunye nezixhobo zokugoba, kwaye zifuna umbhobho wensimbi kunye nezixhobo zokugoba ukuba zibe kwinqanaba.

3. Lungisa isantya sokucinezela i-groove, kwaye i-groove yokwenza ixesha ayinakudlula i-stipulation, sebenzisa amandla ngokulinganayo kwaye ngokuthe ngcembe.

(2) Ukuqhekeka kombhobho wentsimbi ye-groove

1. Lungisa iimbambo ze-welding eludongeni lwangaphakathi lwenxalenye yoxinzelelo lwe-groove yomlomo wombhobho ukunciphisa ukuxhathisa kwe-rolling groove.

I-2, Lungisa i-axis yombhobho wensimbi kunye nezixhobo zokugoba, ezifuna ukuba umbhobho wensimbi kunye nezixhobo zokugoba zibe kwinqanaba.

3. Lungisa isantya sokucofa, isantya esicinezelayo asikwazi ukudlula ummiselo, sebenzisa amandla ngokulinganayo nangokucotha.

4. Khangela ububanzi kunye nemodeli ye-roller yokuxhasa kunye ne-pressure roller ye-rolling groove isixhobo, kwaye ukhangele ukuba kukho ukungahambi kakuhle kwisayizi yee-roller ezimbini, ezinokubangela ukubanjwa.

5. Sebenzisa i-vernier caliper ukujonga ukuba i-groove yombhobho wensimbi icacisiwe.

(3) I-groove eyenziwe ngumatshini we-rolling groove kufuneka ihlangabezane nezi mfuno zilandelayo

I-1, Umphezulu wokuphela kombhobho ukuya kwinqanaba le-groove kufuneka lihambe kakuhle kwaye lingabikho ukungalingani kunye namanqaku e-roll.

I-2, Umbindi we-groove kufuneka ugxininise kunye nodonga lombhobho, ububanzi kunye nobunzulu be-groove kufuneka buhlangabezane neemfuno, kwaye ukhangele ukuba uhlobo lwe-clamp luchanekile.

3. Faka i-lubricant kwiringi yokutywina yerabha kwaye ujonge ukuba iringi yokutywina yerabha yonakele na. Isithambiso akufuneki sibe sisithambiso se-oyile.

Uqhagamshelo oludityanisiweyo

1. Umlomo wombhobho wombhobho wensimbi yensimbi awukho kumgca ochanekileyo kwaye kukho ingxaki yomlomo we-oblique wepayipi yensimbi emva kokuqhawula. Kunconywa ukunqumla intloko yombhobho ixesha elifutshane ngaphambi kokuba kuqhutywe.

I-2, Emva kokuba i-galvanized steel pipe nozzles ixhunyiwe, i-nozzles ezimbini azixhunyiwe ngokuqinileyo, okubangelwa ubuninzi obungalinganiyo bombhobho odibeneyo; kwaye umbhobho u-elliptical ngenxa yezizathu zayo okanye i-bumps yokuthutha. Kunconywa ukunqumla intloko yombhobho ixesha elifutshane. Inkqubo kwakhona.

3. Emva kokuba imibhobho yemibhobho yentsimbi ikhutshiwe, amadyungudyungu avela kwimibhobho:

4. Ngenxa yezizathu zobugcisa ngexesha le-welding.

5. Kukho i-zinc nodules kwi-nozzle, enokubangela ubunzima be-welding kunye ne-blisters. Ukuba i-zinc nodules inkulu kakhulu kwaye ininzi imibhobho, i-zinc nodules elula kufuneka isuswe.

Uqhagamshelo ngocingo

I-1, iqhosha elinemisonto: Ihupu yombhobho kunye nentambo enemisonto ayinakuqhagamshelwa ngokupheleleyo, ikhulule, inqumle inxalenye yebhanti engaqhelekanga, kwaye uphinde ufake umsonto.

2. Intambo yombhobho wensimbi kunye nentambo ye-hoop yepayipi ayifani kwaye ayikwazi ukudibaniswa. I-hoop yombhobho kufuneka itshintshwe okanye isixhobo kufuneka sihlengahlengiswe kwaye siphinde sifakwe umsonto.

3. Ushicilelo olulahlekileyo emva kokuba umbhobho wentsimbi uphothiwe: Linganisa ukuba ubukhulu bodonga lombhobho wentsimbi bungahlangabezana neemfuno zobukhulu bomgangatho wombhobho ophothiweyo.

| Uhlobo | En10210 umbhobho wentsimbi |

| IBanga | S235jrh(1.0039), s275j0h(1.0149), s275j2h(1.0138), s355j0h(1.0547), s355j2h(1.0576), s355k2h(1.0512), (1.0512),. 5.9(1.0512), 7(9), 7(9), 5.9(1.0512), s27(1.0512), s27(1.0149), s275j2h(1.0138), s355j0h(1.0547) s(5,5,5) s420nh(1.8750), s420nlh(1.8751), s460nh(1.8953), s460nlh(1.8956), s235jrh(1.0039), s275j(1.8750), l5(420n), s420n s460nh(1.8953), s235jrh(1.0039), s275j5(j5h), 5j5(04j), 5h(1.8751), 5h(1.8751), s460nh(1.8953) 1.0551.51 s355j2h(1.0552)(1.0493), s275nlh(1.0497), s355nh(1.0539), s355nlh(1.0549), s420nh(1.8750), s420nl5nh6),1.4 s460nlh(1.8956), s275mh(1.8453)(m843)s275ml (s355mlh(1.8846)s420mh(1.8847)s420mlh(1.8848)s460mh(1.8849)s460mlh(1.8850) |

| Ukutyeba | 3mm-30mm |

| Isiqinisekiso | Ul api |

| Inkonzo yokuqhuba | Ukugoba, ukuwelda, ukukhulula, ukubethelwa, ukusika |

| Igama lemveliso | Umbhobho wentsimbi ongenamthungo |

| Ubume | Isikwere esijikelezayo. Uxande |

| Ubude | 3-12m |

| Moq | Itoni e-1 |

| Iteknoloji | Ingqele eshushu isongiwe |