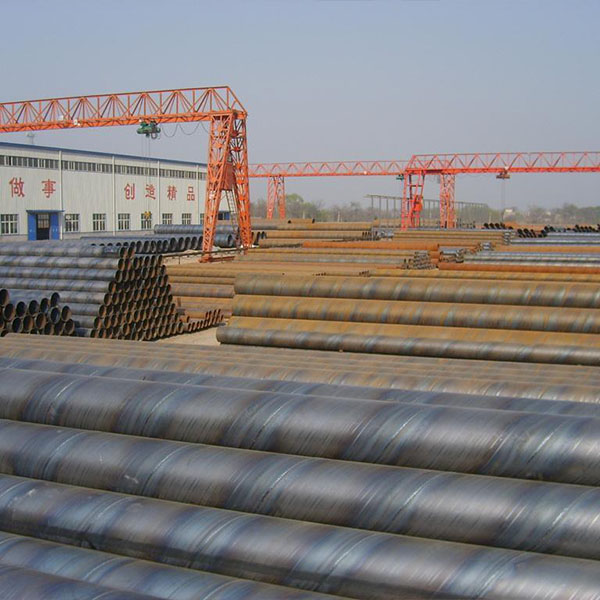

Q235B Spiral Tube

Imigangatho eqhelekileyo esetyenziswayo kwimibhobho yentsimbi ejikelezayo yahlulwe ngokubanzi ibe: SY/T5037-2000 (umgangatho woMphathiswa, okwabizwa ngokuba yi-spiral seam entywiliselweyo i-arc welding yentsimbi yombhobho wemibhobho yokuthutha ulwelo oluqhelekileyo), i-GB/T9711.1-1997 (umgangatho weSizwe, okwabizwa ngokuba Umbhobho wentsimbi wokuhambisa i-oyile negesi Inxalenye yokuqala yeemeko zonikezelo lobugcisa: Umbhobho wentsimbi weBakala A (GB/T9711.2 Grade Umbhobho wensimbi we-B uyimfuneko ngokungqongqo), i-API-5L (i-American Petroleum Institute, ebizwa ngokuba ngumbhobho wentsimbi yombhobho; eyahlulahlulwe ngamanqanaba amabini: PSL1 kunye ne-PSL2), i-SY/T5040-92 (i-Spiral submerged arc welded steel pipe for imfumba).

(1) Iimathiriyeli ekrwada zizikhoyili zentsimbi, iingcingo zokuwelda, kunye ne-fluxes. Ukuhlolwa okungqongqo ngokomzimba kunye neekhemikhali kuyafuneka phambi kotyalo-mali.

(2) Umdibaniso we-butt wentloko yentsimbi kunye nomsila, usebenzisa i-arc-wire okanye i-double-wire submerged arc welding, emva kokudibanisa kumbhobho wentsimbi, ukuwelda kwe-arc okuzenzekelayo kusetyenziselwa ukulungiswa kwe-welding.

(3) Ngaphambi kokuqulunqwa, umgca uhambelana nomgangatho, ukunqunyulwa komphetho, ukucwangciswa komphetho, ukucocwa komphezulu kunye nokuhanjiswa, kunye nokunyangwa kwangaphambili.

(4) I-gauge yokudibanisa yombane isetyenziselwa ukulawula uxinzelelo lweesilinda kumacala omabini omqhubi ukuqinisekisa ukuhanjiswa okugudileyo komcu.

(5) Ukwamkela ulawulo lwangaphandle okanye ukwenziwa koluhlu lolawulo lwangaphakathi.

(6) Isixhobo sokulawula i-weld gap sisetyenziselwa ukuqinisekisa ukuba i-gap ye-weld ihlangabezana neemfuno ze-welding, kunye nobubanzi bombhobho, ubungakanani bokungahambi kakuhle kunye ne-weld gap ilawulwa ngokungqongqo.

(7) Zombini i-welding yangaphakathi kunye ne-welding yangaphandle zamkela umatshini wokuwelda wombane we-American Lincoln we-welding ye-arc enye okanye i-double-wire submerged arc welding, ukuze ufumane iinkcukacha ezizinzileyo ze-welding.

(8) I-Welds ihlolwe nge-intanethi eqhubekayo ye-ultrasonic i-flaw isixhobo esizenzekelayo, esiqinisekisa i-100% yovavanyo olungonakalisi ukugubungela i-spiral welds.

(9) Sebenzisa umatshini wokusika iplasma yomoya ukusika umbhobho wentsimbi ube ngamaqhekeza ngamanye.

10

(11) Amalungu aneempawu eziqhubekayo zokufumanisa i-sonic flaw kwii-welds ziphinda zihlolwe i-ultrasonic manual kunye ne-X-ray.

(12) Imibhobho apho umthungo wentsimbi uthungelwa ngeempundu kunye namalungu amile okwe-D anqumla imithungo ye-welding ejiyileyo yonke ihlolwa ngomabonakude weX-reyi okanye ukufotwa.

(13) Ipayipi nganye yensimbi ifumana uvavanyo loxinzelelo lwe-hydrostatic, kwaye uxinzelelo luthatha i-radial seal. Uxinzelelo lovavanyo kunye nexesha lilawulwa ngokungqongqo ngumbhobho wensimbi we-hydraulic microcomputer isixhobo sokubona. Iiparamitha zovavanyo ziprintwa ngokuzenzekelayo kwaye zirekhodwe.

(14) Umbhobho ekupheleni machining, ukwenzela ukuba nkqo yobuso ekupheleni, i-engile bevel kunye edge obtuse inokulawulwa ngokuchanekileyo.

I-Spiral seam entywiliselwe i-arc welded steel pipe (SY5036-83) yokuthutha ulwelo olunoxinzelelo isetyenziswa ikakhulu kwimibhobho yokuthutha ioyile negesi yendalo; spiral umthungo high-frequency welded umbhobho wentsimbi (SY5038-83) yokuthutha ulwelo olunoxinzelelo, kusetyenziswa indlela ye-welding ye-high-frequency lap Welded, spiral seam high-frequency welded welding pipe yokuthutha ulwelo olunoxinzelelo. Umbhobho wensimbi unamandla okunyamezela uxinzelelo kunye neplastiki enhle, efanelekileyo kwi-welding kunye nokusebenza. Ngokubanzi, i-spiral seam entywiliselweyo i-arc welded steel pipe (SY5037-83) yothutho oluphantsi loxinzelelo lwe-arc lwenziwa ngokudibanisa kwe-arc kumacala amabini oluzenzekelayo okanye ukuwelda kwicala elinye emanzini, umbhobho wentsimbi odityanisiweyo we-arc wokuhambisa ulwelo oluphantsi ngokubanzi. ezifana negesi, umoya kunye nomphunga