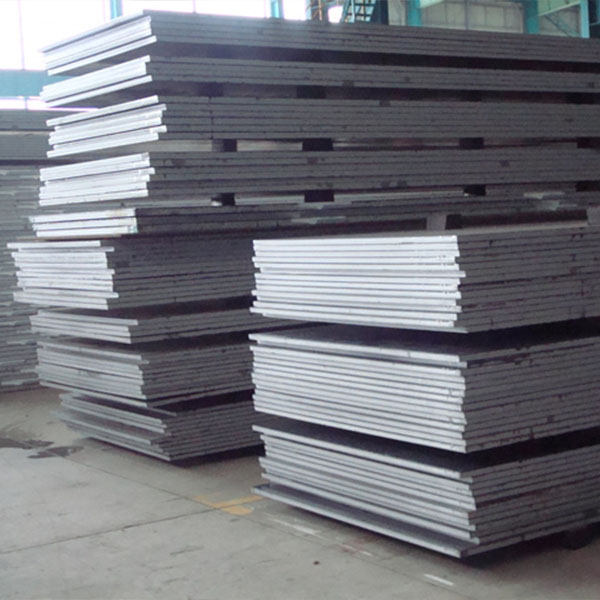

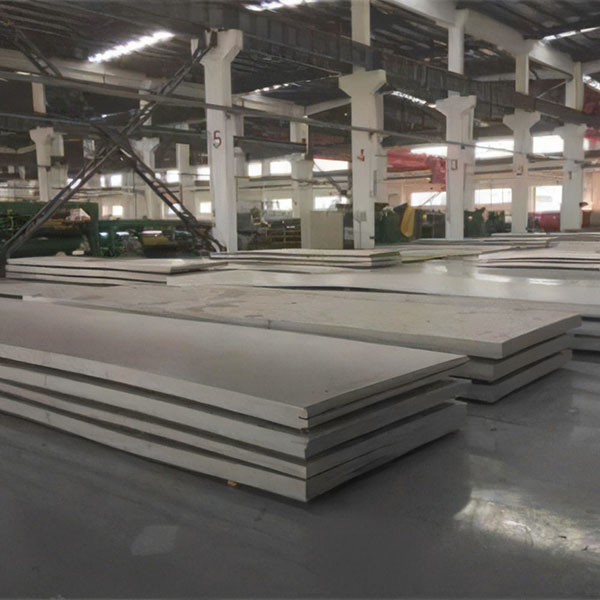

Ipleyiti yentsimbi yentsimbi yoxinzelelo lweVessel

Ludidi olukhulu lweplate yentsimbi-isitya kunye nokubunjwa okukhethekileyo kunye nokusebenza

Isetyenziswa ikakhulu njengesitya soxinzelelo. Ngokweenjongo ezahlukeneyo, ubushushu kunye nokumelana nokubola, izinto zeplate yesitya kufuneka zihluke.

Ukunyangwa kobushushu: ukuqengqeleka okushushu, ukuqengqeleka okulawulwayo, ukuqheleka, ukuthambisa + ukuqunjelwa, ubushushu + ukucima (ukucima kunye nokuqumbisa)

Njenge: Q345R, 16MnDR, 14Cr1MoR, 15CrMoR, 09MnNiDR, 12Cr2Mo1R, Q345R (HIC), 07MnCrMoVR, 13CrMo44, 13MnNiMo54

Ezi zingasentla ziziphawulo zaseTshayina, kwaye zininzi iimpawu zangaphandle.

Ezinje: SA516Gr60, SA516Gr65, SA516Gr70, P355GH, P265GH njalo njalo.

Ukuthelekiswa kwemixholo ephambili yemigangatho emitsha kunye nendala kwiiplate zetsimbi kwiibhoyili kunye neenqanawa zoxinzelelo

Isetyenziswa kakhulu kwi-petroleum, kwishishini lemichiza, kwisikhululo samandla, kwibhoyila kunye nakwamanye amashishini, esetyenziselwa ukwenza ii-reactors, izitshintshi-bushushu, izahluli, iitanki ezingqukuva, iitanki ze-oyile nerhasi, iitanki zerhasi enyibilikisiweyo, amaqokobhe oxinzelelo lwesixhobo senyukliya, imigqomo yebhoyila, i-oli enyibilikisiweyo negesi. iisilinda, Abasebenzisi baneliseke kakhulu zizixhobo kunye namacandelo afana nemibhobho yamanzi yoxinzelelo oluphezulu lwezikhululo zombane kunye I-injini yomoya inamandla. I-Wusteel iseke i-boiler steel plate ekhethekileyo yesebe lophando lwenzululwazi, elilingana ngokupheleleyo nokwamkela imigangatho yangaphandle ukulungiselela ukuveliswa kweepleyiti zensimbi zebhoyila zemigangatho eyahlukeneyo, iimpawu kunye neenkcukacha.

Ukuhlelwa ngokobukhulu

Ipleyiti yentsimbi ebhityileyo <4 mm (eyona thinnest 0.2 mm), ipleyiti yentsimbi eshinyeneyo 4-60 mm, ipleyiti yentsimbi eyongezelelweyo 60-115 mm. Ububanzi beplate encinci yi-500-1500 mm; ububanzi bepleyiti eshinyeneyo yi-600-3000 mm. Uhlobo lwentsimbi yentsimbi eshinyeneyo ipleyiti Ngokusisiseko iyafana nepleyiti yentsimbi ebhityileyo. Ngokweemveliso, ukongeza kwiipleyiti zentsimbi zebhulorho, iipleyiti zensimbi zebhoyila, iipleyiti zentsimbi zokwenza iimoto, iipleyiti zentsimbi zoxinzelelo kunye nomgangatho ophezulu wentsimbi yoxinzelelo oluphezulu, eziziipleyiti ezishinyeneyo, ezinye iintlobo zeepleyiti zentsimbi ezinjengemoto. iipleyiti zentsimbi zentsimbi (ubukhulu be-2.5-10 mm), ipateni Iipleyiti zentsimbi (ubukhulu be-2.5-8 mm), iipleyiti zensimbi ezingenasici, iipleyiti zetsimbi ezikwazi ukumelana nobushushu; njl. zigqitywe ngamacwecwe amancinci. 2. Intsimbi yensimbi ihlulwe ibe yi-hot-rolled and cold-rolled ngokwe-rolling.

Ihlelwa ngokwenjongo

(1) Ipleyiti yentsimbi yebhulorho (2) Ipleyiti yentsimbi yebhoyila (3) Ipleyiti yentsimbi yokwakha umkhumbi (4) Ipleyiti yentsimbi yeSikhali (5) Ipleyiti yentsimbi yemoto (6) Ipleyiti yentsimbi yophahla (7) Ipleyiti yentsimbi yesakhiwo (8) Ipleyiti yentsimbi yoMbane (isilicon) sheet sheet) (9) Ipleyiti yentsimbi yasentwasahlobo (10) Okunye

Ihlelwa ngokwesakhiwo

1. Ipleyiti yensimbi yomkhumbi woxinzelelo: Sebenzisa inkunzi R ukubonisa ekupheleni kwebakala. Ibakala lingabonakaliswa ngenqaku lesivuno okanye umxholo wekhabhoni okanye izinto ezixubeneyo. Njenge: Q345R, Q345 inqaku lesivuno. Omnye umzekelo: 20R, 16MnR, 15MnVR, 15MnVNR, 8MnMoNbR, MnNiMoNbR, 15CrMoR, njl. Zonke zimelwe ngumxholo wekhabhoni okanye i-alloying elements.

2. Ipleyiti yensimbi ye-welding gas cylinders: Sebenzisa i-capital HP ukubonisa ekupheleni kwebakala, kwaye ibakala layo lingabonakaliswa ngenqaku lesivuno, njenge: Q295HP, Q345HP; inokuphinda ibonakaliswe ngezinto ezidibanisayo, ezifana: 16MnREHP.

3. Ipleyiti yentsimbi kwibhoyila: Sebenzisa unobumba omncinci g ukubonisa ekupheleni kwegama lebrendi. Ibakala layo lingabonakaliswa ngenqaku lesivuno, njenge: Q390g; inokuphinda ibonakaliswe ngumxholo wekhabhoni okanye i-alloying elements, njenge-20g, 22Mng, 15CrMog, 16Mng, 19Mng, 13MnNiCrMoNbg, 12Cr1MoVg, njl.

4. Iipleyiti zentsimbi yeebhulorho: Sebenzisa unobumba omncinci q ukubonisa ekupheleni kwebakala, njenge-Q420q, 16Mnq, 14MnNbq, njl.

5. Ipleyiti yensimbi ye-automobile beam: Sebenzisa i-capital L ukubonisa ekupheleni kwebakala, njenge-09MnREL, 06TiL, 08TiL, 10TiL, 09SiVL, 16MnL, 16MnREL, njl.

| Isitya sebhoyila, ipleyiti yesikhongozeli ibalwe ubunzima | ||||

| Ubukhulu begama | Ukutyeba okongeziweyo ixabiso | |||

| ≤1500 | >1500~2500 | >2500~4000 | >4000~4800 | |

| 3.00~5.00 | 0.25 | 0.35 | ---- | |

| 6.00~8.00 | 0.3 | 0.45 | ---- | |

| 9.00~15.0 | 0.35 | 0.5 | 0.6 | |

| 16.0 ~ 25.0 | 0.45 | 0.6 | 0.8 | |

| 26.0~40.0 | 0.5 | 0.7 | 0.9 | |

| 41~60.0 | 0.6 | 0.8 | 1 | |

| 61.0~100 | 0.75 | 1 | 1.2 | |

| 101-150 | 1.1 | 1.3 | 1.5 | |

| 151-200 | 1.3 | 1.5 | 1.6 | |

| 201-250 | 1.5 | 1.7 | 1.9 | |

| 251~300 | 1.7 | 1.9 | 2.1 | |

| 301~400 | 1.9 | 2.1 | 2.3 | |

Uxinzelelo oluphantsi lobushushu besitya sentsimbi yentsimbi kunye ne-Ultra-low low steel SA203E iinkcukacha ze-8-100mm, 09MnNiDR iinkcukacha 8-120mm, 15MnNiDR iinkcukacha 8-120mm, 16MnDR iinkcukacha 8-120mm.

Iipleyiti zetsimbi kwiinqanawa zoxinzelelo

16MnR, 20R, 15CrMoR, 15MnVR, SA516Gr60, SA516Gr70, 20g, SA285GrC, 16Mng, 410B, 07MnNiMoVDR, SA387Gr22CL2, SA387Gr22CL2, SA2CL8Gr72;1 SA387Gr3CL8CL877Gr3, SA3872Gr3, SA387Gr3G,16Mng I-AISI4140, SA285GrCM, SB410, KP42, 370 A516Gr60, A516Gr70, P235GH, P295GH, P355GH, 19Mn6, 15Mo3, 16Mo3, A537CL1, sa622MrCMo, 1RN8MR4GNR, 1537CL1, sa622GNRCP4GNR8G4G A515Gr65, A516Gr65, SA612M, A537CL2,SB450.

Iipleyiti zetsimbi kwiinqanawa zoxinzelelo kunye neepleyiti ze-boiler drum

20g, 16Mng, 15CrMog, 12Cr1MoVg, 19Mng, 22Mng, 13MnNiCrMoNbg, 20R.16MnR, 15MnVR, 15CrMoR, 13MnNiMoNbR, 15MnBRn, DR6Mn, DRV1 09MnNiDR, 15MnNiDR, 12Cr2Mo1R, 14Cr1MoR, 07MnCrMoVR, 07MnNiCrMoVDR, 15MnNiDR, SB410, SB450, SGV480, SBV1A, SBV3 SEV5 SEV5 SEV5, 2V5 SEV5 SEV5, 5SEV5 SEV5 SEV345, 10CrMo910, 15Mo3, 13CrMo44, 19Mn6, BHW35, 13MnNiMo54, 1Cr05Mo, 2.25Cr1Mo, 1.25Cr0.5Mo, (S)A299M, (0M, 6, 5 G5), 6 (S) (S)A204M(Gr, A, B, C), (S)A387M(Gr11, 12, 22), (S)A537M(GL.1, GL.2),(S)A622M(Gr.A, B , C),(S)A302M(Gr.A, B, C), (S)A737M(Gr.B, C), (S)A738M(Gr.A, B, C), (S)A533M(I, II), P235GH, P265GH, P295GH, P355GH, 16Mo3, 13CrMo4-5, 10CrMo9-10, 11CrMo9-10, A42, A42, 20MnHR, 20HR, 16MnHR, 161G430, WDB620.