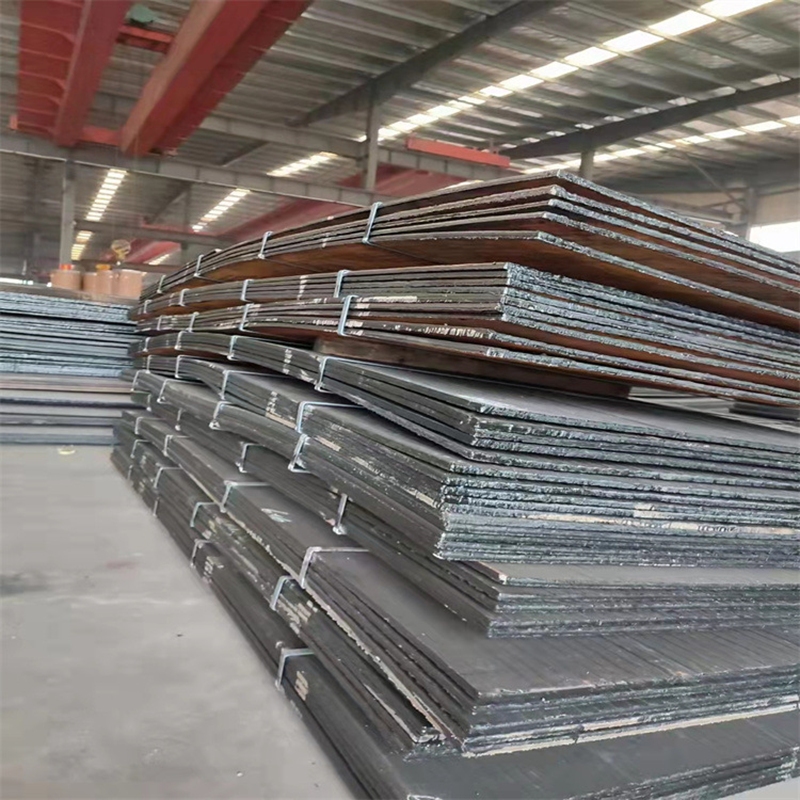

1. Isishwankathelo sepleyiti yentsimbi enganxitywayo

Nxiba i-Resistant Steel Plate, oko kukuthi ipleyiti yentsimbi engagugiyo, yimveliso yepleyiti ekhethekileyo esetyenziswa ngokukodwa phantsi kweemeko zokusebenza zokunxiba kwindawo enkulu. Yenziwe ngepleyiti yentsimbi ephantsi kwekhabhoni kunye ne-alloy ekwazi ukumelana nokunxiba.

Ipleyiti yentsimbi ekwaziyo ukunxiba ineempawu zamandla aphezulu kunye nokumelana nokunxiba okuphezulu. Umaleko we-alloy onganyangekiyo ngokuqhelekileyo yi-1/3 ukuya kwi-1/2 yobukhulu obupheleleyo. Xa usebenza, i-matrix inikezela ngeempawu ezibanzi ezifana namandla, ukuqina kunye neplastiki ukuxhathisa amandla angaphandle, kunye ne-alloy wear-resistant layer inikezela ukuxhathisa ukunxiba ukuhlangabezana neemfuno zeemeko zokusebenza ezichaziweyo.

Kukho iindidi ezininzi zeepleyiti zentsimbi ezikwaziyo ukunxiba, kubandakanywa iipleyiti zentsimbi ezidityanisiweyo kunye ne-alloy ecinyiweyo. Umzekelo, i-KN60 ipleyiti yentsimbi ekwaziyo ukunxiba luhlobo lwemveliso eyenziwe ngokudityaniswa kongqimba oluthile lwe-alloy-resistant layer enobunzima obuphezulu kunye nokumelana okugqwesileyo kumphezulu wentsimbi ye-carbon low-carbon okanye i-low-alloy steel enokuqina okuhle. kunye neplastiki ngokusebenzisa indlela yokujonga phezulu. Iiparamitha zobugcisa be-KN60 i-plate yensimbi engaguqukiyo yile ilandelayo: ubunzima beVickers yi-1700HV; izinto eziphathekayo ziphantsi kwe-carbon steel base, kunye nezinye iintlobo ze-alloys ezinzima kunye ne-niobium carbide zinokubonelelwa ngokweemfuno. I-chromium kunye ne-boron alloy carbides zizityebi; ukuqina komgangatho odibeneyo wokunxiba i-C62-65 HRc; ubukhulu buyi-3 - 15 millimeters; umxholo we-alloy onzima ungaphezulu kwe-50%; ubushushu obuphezulu bokusebenza yi-1000°C.

Ukongeza, ipleyiti yentsimbi engama-360 exhathisayo luhlobo lwamandla aphezulu kunye nomgangatho ophezulu wokunxiba. Yenziwe ngetekhnoloji ye-prestressing kwaye inamandla angcono okuqina kunye namandla acinezelayo, kunye nokuxhathisa okuhle kokunxiba kunye nokumelana nempembelelo.

2. Ukusetyenziswa kweepleyiti zentsimbi ezinxitywayo

2.1 Uluhlu olubanzi lwezicelo zamashishini

Iipleyiti zentsimbi ezikwaziyo ukunxiba zifumana ukusetyenziswa okubanzi kumashishini ahlukeneyo. Kwishishini le-metallurgical, zisetyenziselwa izixhobo ezifana ne-crusher kunye namabhanti okuhambisa, ahlala ephantsi kwe-abrasion kunye nefuthe. Kumashishini amalahle, baqeshwe kwiichute zamalahle kunye neendawo zoomatshini bemigodi ukumelana neemeko ezinzima zokunxiba. Ishishini lesamente lisebenzisa iipleyiti zentsimbi ezingagugiyo kwiikontini nakwizingqusho zokusila ukuqinisekisa ubomi benkonzo ende. Kwishishini lamandla, zisetyenziswa kwizixovulelo zamalahle kunye neenkqubo zokuphatha uthuthu.

Ngokomzekelo, ipleyiti yensimbi engaguqukiyo i-360 isetyenziswa ngokubanzi kwiimoto, umzila kaloliwe, inqwelomoya, isinyithi, imboni yeekhemikhali, oomatshini, i-petroleum, umbane, ukugcinwa kwamanzi kunye nokwakhiwa. Ilungele amacandelo athwala imithwalo yempembelelo enkulu koomatshini bemizi-mveliso ngenxa yokunganyangeki kwayo okugqwesileyo, ukuxhathisa impembelelo, kunye nokuxhathisa umhlwa.

2.2 Ukusebenza kakuhle kweendleko

Xa kuthelekiswa nezinye izinto, iipleyiti zentsimbi ezinxibayo zibonelela ngeendleko eziphezulu zokusebenza. Nangona iindleko zokuqala zeepleyiti zetsimbi ezingagugiyo zinokuthi ziphakame kancinci kunezinye izinto zendabuko, ukuxhathisa kwazo okuphezulu kunye nokuqina kukhokelela ekugcinweni okubalulekileyo ekuhambeni kwexesha. Ngokomzekelo, inkampani esebenzisa iipleyiti zentsimbi ezingagungqiyo kwinkqubo yayo yokuvelisa inokufumana ixesha elincitshisiweyo lokugcinwa kwezixhobo kunye nokutshintshwa, okukhokelela ekunyuseni kwemveliso kunye nokonga iindleko.

Ngokutsho kwedatha, ubomi benkonzo yeepleyiti zetsimbi ezinxibayo zihlala ziphindwe kaninzi kuneeplate zetsimbi eziqhelekileyo. Oku kuthetha ukuba iinkampani zinokunciphisa iindleko zazo zempahla kunye neendleko zokuzilungisa ekuhambeni kwexesha. Ukongezelela, ukusebenza okugqwesileyo kweepleyiti zetsimbi ezinxitywayo zinciphisa umngcipheko wokungaphumeleli kwezixhobo kunye nokulibaziseka kwemveliso, ngakumbi ukuphucula izibonelelo zabo zoqoqosho. Ngenxa yoko, amashishini amaninzi kunye nabavelisi babonisa ukukhetha kwiipleyiti zetsimbi ezingagugi.

3. Ukuhlelwa kwezinto eziphathekayo kwiipleyiti zetsimbi ezinxibayo

3.1 Iintlobo zezinto eziqhelekileyo

Iipleyiti zentsimbi ezikwaziyo ukunxiba ziqhele ukwenziwa ngokubeka i-alloy-resistant layers kumphezulu wentsimbi eqhelekileyo enekhabhoni ephantsi okanye intsimbi ephantsi. Kukwakho neepleyiti zentsimbi ezinganxibiyo kunye neepleyiti zentsimbi ezicimayo. Umzekelo, ipleyiti yentsimbi enganyangekiyo edityanisiweyo yenziwa ngokudityaniswa kobunzima obuthile be-alloy-resistant layer kunye nobunzima obuphezulu kunye nokumelana okugqwesileyo kwisiseko sesinyithi.

3.2Iindidi ezahlukeneyo zeempawu

Kukho ubukhulu becala iintlobo ezintathu zeepleyiti zentsimbi ezinxitywayo: uhlobo lwenjongo jikelele, uhlobo oluchasene nempembelelo, kunye nohlobo olunobushushu obuphezulu.

I-plate yensimbi engaguqukiyo yenjongo eqhelekileyo inomsebenzi ozinzile kwaye ifanelekile kwiimeko zokugqoka ngokubanzi. Inokumelana nokunxiba kakuhle kunye namandla aphakathi. Iiparamitha zobugcisa zinokubandakanya umgangatho othile wobulukhuni, oqhelekile malunga ne-50-60 HRC. Ukwakhiwa kwemathiriyeli ngokuqhelekileyo kuqulethe izinto ezinje ngechromium kunye nemanganese ukomeleza ukumelana nokunxiba. Kwintsebenzo, inokumelana neqondo elithile lokukrazula kwaye isetyenziswa ngokubanzi kumashishini afana nokuveliswa koomatshini.

Ipleyiti yentsimbi enganyangekiyo kwimpembelelo yentsimbi yenzelwe ukumelana neempembelelo ezinzima. Inokuqina okuphezulu kunye nokumelana nempembelelo ebalaseleyo. Izinto eziphathekayo zihlala ziqulethe izinto ze-alloy ezandisa ukuchasana kwayo neempembelelo. Umzekelo, ezinye iipleyiti zentsimbi ezinganyangekiyo kwimpembelelo zinokuba lukhuni malunga ne-45-55 HRC kodwa zinempembelelo ephezulu yokuchasa. Olu hlobo lufanelekile kwizicelo apho izixhobo ziphantsi kweempembelelo eziqhelekileyo, ezifana nemigodi kunye nemizi-mveliso yokwakha.

Ipleyiti yentsimbi ekwazi ukumelana nobushushu obuphezulu inokumelana namaqondo obushushu aphezulu. Yenziwe ngezinto ezikhethekileyo ze-alloy ezinokugcina uzinzo kumaqondo okushisa aphezulu. Iiparamitha zobugcisa zinokubandakanya ubushushu bokusebenza obuphezulu ukuya kuma-800-1200°C. Ukubunjwa kwezinto ngokuqhelekileyo kuqulethe izinto ezifana ne-nickel kunye ne-chromium ukuqinisekisa ukuchasana nobushushu obuphezulu. Ekusebenzeni, isetyenziswa ngokubanzi kwiindawo ezinobushushu obuphezulu njengeziko kunye neekhilni kumashishini e-metallurgical kunye nesamente.

Ixesha lokuposa: Oct-31-2024