I-Laser Tailor-Welded Boiler Plate

Ezothutho: Xhasa uthutho lwaselwandle

Imigangatho: AiSi, ASTM, JIS

IBakala: Ar360 400 450 NM400 450 500

Indawo yemvelaphi: Shandong, China

Umzekelo: Ar360 400 450 NM400 450 500

Uhlobo: ipleyiti yensimbi, ipleyiti yensimbi

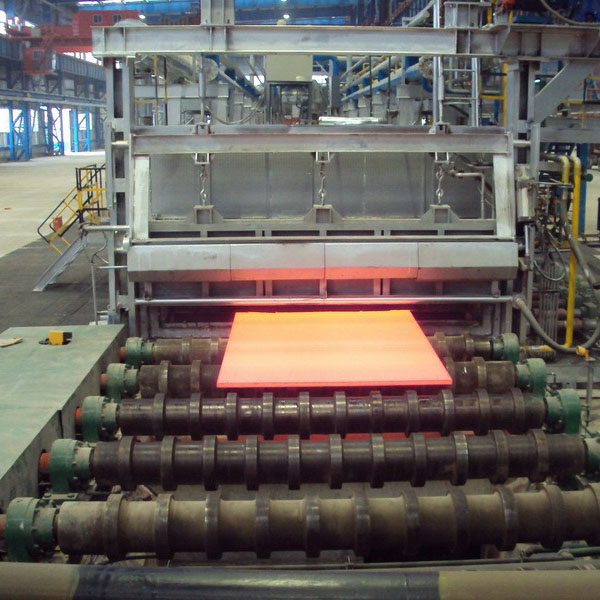

Inkqubo: Ishushu

unyango Surface: ukutyabeka

Isicelo: i-boiler plate

Ububanzi: 2000mm okanye njengoko kufuneka

Ubude: 5800mm 6000mm 8000mm

Ukunyamezela: ±5%

Iinkonzo zokulungisa: ukugoba, ukuwelda, ukukhulula, ukusika, ukubethelwa

Igama leMveliso: Ipleyiti yentsimbi enganxibiyo

Izinto eziphathekayo: NM450 500 550 640 NM4400 450 500

Ukutyeba: 3mm-100mm okanye njengoko kufuneka

Ukupakishwa: Ukupakishwa okusemgangathweni komoya

Usetyenziso: Ishishini

Ubume: uxande

Ukubonelela ngeSakhono: 2000 tons/toni ngenyanga

Iinkcukacha zokupakisha: ukupakisha okuphezulu komoya, kwakhona ngokweemfuno zabathengi.

Izibuko: Qingdao, Tianjin, Shanghai

Ukuphuhliswa kwe-20g kwiJinan Iron kunye ne-Steel Group Corporation (efinyeziweyo njengeJigang) yenziwa ngaphezu kweminyaka elishumi edlulileyo, kodwa ilinganiselwe kwinqanaba lezixhobo zenkqubo kunye nezixhobo ngelo xesha, ukusebenza kwepleyiti yentsimbi kwakungazinzanga, kwaye kwakukho. amaxesha amaninzi iingxaki zokugoba okubandayo kunye neempawu zokuguga. La manyathelo alandelayo aya kuthathwa ukuphucula ukugoba okubandayo kunye neempawu zokuguga kunye nokuqinisekisa ukuqina kwempembelelo yobushushu obuphantsi:

(1) Ukulungelelanisa amacandelo olawulo lwangaphakathi kunye nokwandisa umda ophantsi womxholo we-manganese ukuya kwi-0.65%.

(2) Umsebenzi wokucoca "uBathathu Emnye" wokutyisa ucingo, ukulawulwa kweqondo lokushisa kunye nokuvuthela kwe-argon kwamkelwa.

(3) Lawula ngokungqongqo ubushushu bokugalela.

(4) Umxholo we-microalloyed element Ti unyuke ukusuka kwi-0.003% ukuya ngaphezu kwe-0.008%. (5) Yonke inkqubo yokugalela yokukhusela yamkelwa ukunciphisa ukufunxa n

Indlela yenkqubo yemveliso:I-20g (Ti) ipleyiti yebhoyila luhlobo lwentsimbi eneemfuno eziphezulu zeempawu ezibanzi zoomatshini, intsimbi esulungekileyo ngokwentelekiso, kunye nokubunjwa kwamacandelo okunyibilika kunye nezinto ezixubeneyo ezithi zichaphazeleke ngakumbi kwiziphumo zeempawu ezahlukeneyo. Ngoko ke, isitshixo kwinkqubo yokuvelisa i-20g (Ti) kukwandisa ukubunjwa kokunyibilika, ukunciphisa inani elipheleleyo lokubandakanywa kwintsimbi, khetha izinto ezifanelekileyo ze-microalloying, ukusebenzisa ukuqengqeleka okulawulwayo, ukuphucula umgangatho wepleyiti, kunye nokuzinzisa ukusetyenziswa kweplate. impembelelo yokuguga. Indlela yobuchwephesha ye-20g yile: umgangatho ophezulu wentsimbi enyibilikisiweyo → unyango lokucoca → ukunyibilikiswa kokulungelelaniswa kokwakheka kunye nokucocwa kwentsimbi → i-microalloying kunye nokusulungekiswa kwentsimbi etyhidiweyo → ukuphosa okukhuselekileyo → i-slab ekumgangatho ophezulu → ukufudumeza okulawulwayo → ukuqengqeleka okulawulwa ngubushushu → imilo yepleyiti kunye ulawulo lokutyeba →Lawula ukupholisa→imveliso.

I-Laser i-welded-welded blank kunye ne-teknoloji yebhodi eguquguqukayo eqhubekayo

1. I-Tailor Welded Blanks (i-Tailor Welded Blanks, i-TWB) isebenzisa i-laser njengomthombo wokushisa we-welding ukudibanisa kunye nokuwelda izinto ezininzi ezahlukeneyo, ubukhulu obuhlukeneyo, kunye neengubo ezahlukeneyo zentsimbi, i-stainless steel, i-aluminium alloy, njl. kwipleyiti epheleleyo.

2. Ukusebenzisa itekhnoloji yokuwelda elungiselelwe i-laser, kunokwenzeka ukudibanisa ngokufanelekileyo izixhobo zobukhulu obahlukeneyo kunye namanqanaba amandla ngokweemeko zoxinzelelo lwamalungu olwakhiwo, ukuphucula ubulukhuni besakhiwo ngelixa unciphisa ubunzima bamalungu, kwaye ukwandise izinga lokusetyenziswa. zemathiriyeli kunye nokunciphisa inani lamalungu. Inani lamalungu kwi lula inkqubo. Itekhnoloji yokuwelda eyenziwe ngeLaser iye yaba yeyona ndlela iphambili yobugcisa bemoto ekhaphukhaphu, kwaye isetyenziswe kwiimodeli zabenzi abaninzi. Ikakhulu isetyenziswa ngaphambili nangasemva iipaneli zangaphakathi zomnyango, ngaphambili nangasemva iipali zobude, iipaneli zecala, iipaneli zomgangatho, i-A, B, kunye ne-C iintsika ngaphakathi kocango, izigqubuthelo zamavili kunye neepaneli zangaphakathi ze-trunk, njl.

3. I-Tailor Rolling Blanks (TRB), ekwabizwa ngokuba yi-different thicknessal plates, ibhekisela kutshintsho lwexesha lokwenene lobungakanani besithuba se-roll ngokusebenzisa ikhompyutha ngexesha lokuqengqeleka kwepleyiti yentsimbi, ukuze ipleyiti ebhityileyo igqitywe ngaphambili. isalathiso ecaleni kwendlela yokuqengqeleka. Ubume obunqamlezileyo obuqhelekileyo.

4. Itekhnoloji yephaneli yephaneli eguquguqukayo eqhubekayo isetyenziswe ngokubanzi ekwenziweni kwamalungu esakhiwo somzimba, njengesigqubuthelo se-injini, intsika ye-B, i-chassis yomzimba, isikhokelo se-motor spacer, ikholamu ephakathi ipaneli yangaphakathi, i-mudguard kunye nebhokisi yokuphahlazeka, njl. kwaye isetyenziswe ngempumelelo kwi-Audi, BMW, Volkswagen, GM kunye nezinye iimodeli.

5. I-laser ye-welding ye-laser kunye ne-teknoloji eqhubekayo eguquguqukayo ye-cross-section iguqula ubukhulu bezinto zokunyathelisa ngeendlela ezahlukeneyo zobuchwepheshe, kwaye zisetyenziselwa ukusombulula ingxaki yeemfuno ezahlukeneyo zomthwalo womthwalo kwiindawo ezahlukeneyo zeengxenye ze-auto phantsi komthwalo. Xa kuthelekiswa nezi zimbini, inzuzo yetekhnoloji ye-laser welding eyenziwe ngokwezifiso ilele ekuguquguqukeni kwayo, okunokuqonda ukudibanisa kwaso nasiphi na isikhundla kunye ne-splicing yezinto ezahlukeneyo. Inzuzo yetekhnoloji eqhubekayo eguquguqukayo yecandelo letekhnoloji kukuba akukho mthungo we-welding, ukuqina kokutshintsha kwicala lobude kuthambile, kunokwakheka okungcono, kwaye umgangatho womphezulu ulungile, ukusebenza kakuhle kwemveliso kuphezulu, kwaye ixabiso liphezulu. phantsi. Imithwalo, izixhobo zonyango, iqokobhe lesithuthuthu; imoto, uphahla lwangaphakathi lwebhasi, ideshibhodi; ukuxhaswa kwesihlalo, iphaneli yomnyango, isakhelo sefestile, njl.

| A516 Gr.60 | A516 Gr.65 | A516 Gr.70 | |

| Amandla Okuqina (Ksi) | 60-80 | 65-85 | 70-90 |

| Amandla Okuqina (Mpa) | 415-550 | 450-585 | 485-620 |

| Isivuno Amandla (Ksi) | 32 | 35 | 38 |

| Isivuno Amandla (Mpa) | 220 | 240 | 260 |

| 200mm Ubude (%) | 21 | 19 | 17 |

| 50mm Ubude (%) | 25 | 23 | 21 |

| Ukutyeba okuphezulu (Mm) | 205 | 205 | 205 |