Ipleyiti eHolisiweyo yentsimbi engatyiwayo

Kufuneka ukwazi ukumelana nokugqwala kwe-oxalic acid, i-sulfuric acid iron sulfate, i-nitric acid, i-nitric acid hydrofluoric acid, i-sulfuric acid sulfate yobhedu, i-phosphoric acid, i-formic acid, i-acetic acid kunye nezinye ii-acids. Isetyenziswa ngokubanzi kushishino lweekhemikhali, ukutya, amayeza, ukwenza iphepha, i-petroleum, amandla e-athomu kunye namanye amashishini, kunye neendawo ezahlukeneyo zezakhiwo, i-kitchenware, i-tableware, izithuthi kunye nezixhobo zendlu. Ukuze kuqinisekiswe ukuba iipropathi zoomatshini ezifana nokuqina kwesivuno, amandla okuqina, ukunyuswa kunye nobulukhuni beepleyiti ezahlukeneyo zetsimbi ezingenasici zihlangabezana neemfuno, iipleyiti zetsimbi kufuneka zenze unyango olushushu olufana ne-annealing, unyango lwesisombululo kunye nonyango lokuguga ngaphambi kokunikezelwa.

Ipleyiti yensimbi engenasici inomgangatho ogudileyo, iplastiki ephezulu, ukuqina kunye namandla omatshini, kwaye iyamelana nokubola kweasidi, igesi yealkaline, isisombululo kunye nolunye uhlobo lweendaba. Luhlobo lwentsimbi yealloyi ekungekho lula ukurusa, kodwa alunarusi kwaphela.

Ukuxhatshazwa kwe-corrosion yensimbi engenasici ngokuyinhloko kuxhomekeke ekubunjweni kwe-alloy yayo (i-chromium, i-nickel, i-titanium, i-silicon, i-aluminium, njl.) kunye nesakhiwo sangaphakathi. I-Chromium idlala indima enkulu. I-Chromium inozinzo oluphezulu lweekhemikhali, inokwenza ifilimu engabonakaliyo kwindawo yentsimbi, ihlukanise isinyithi ngaphandle, ikhusele ipleyiti yensimbi kwi-oxidation kwaye inyuse ukuxhathisa kwe-corrosion ye-steel plate. Emva kokuba ifilimu ye-passivation ibonakaliswe, ukuxhathisa kwe-corrosion kunciphisa.

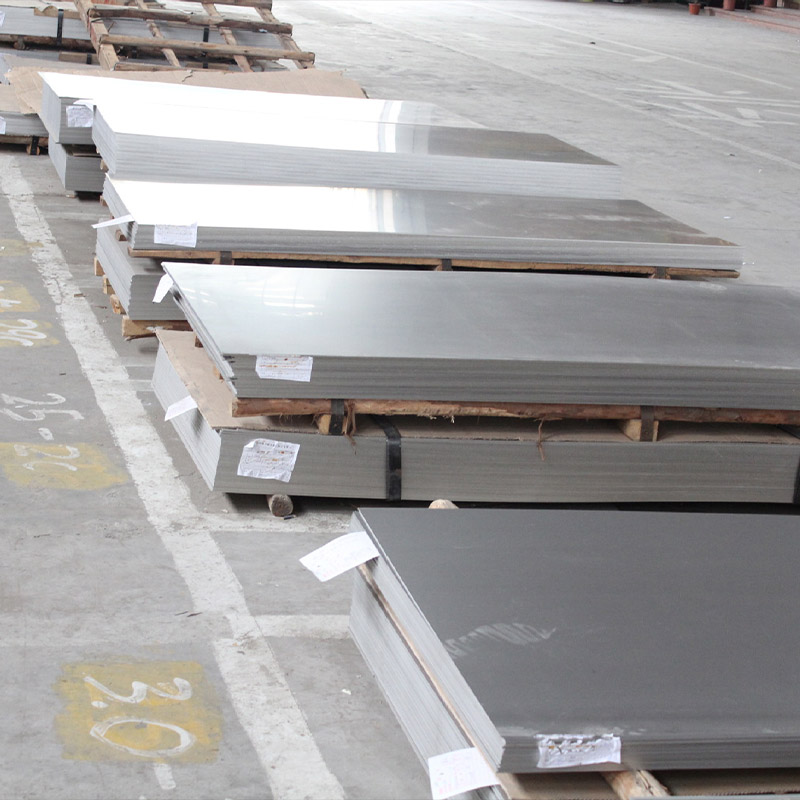

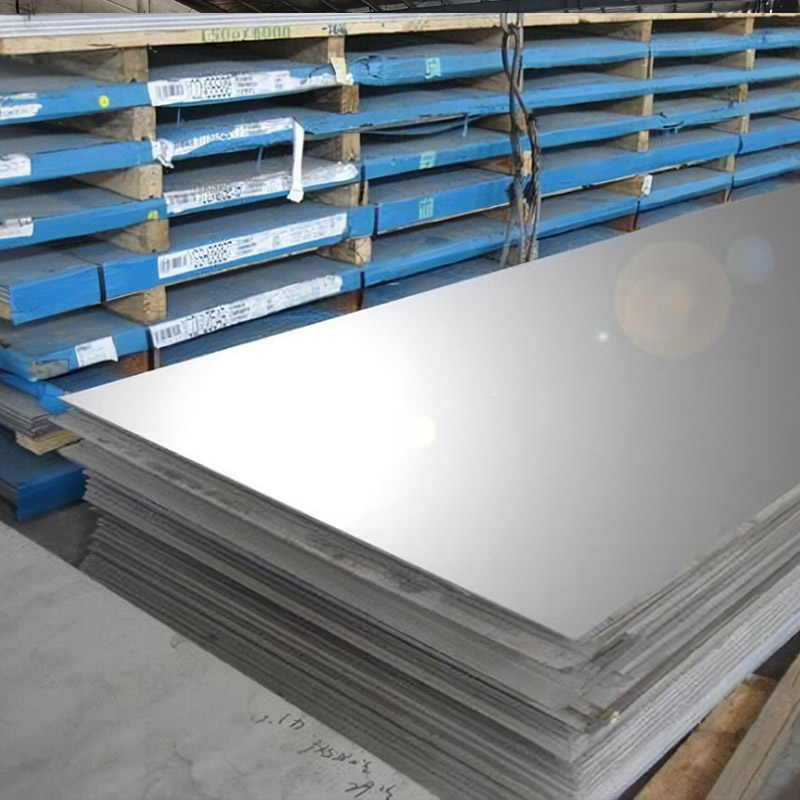

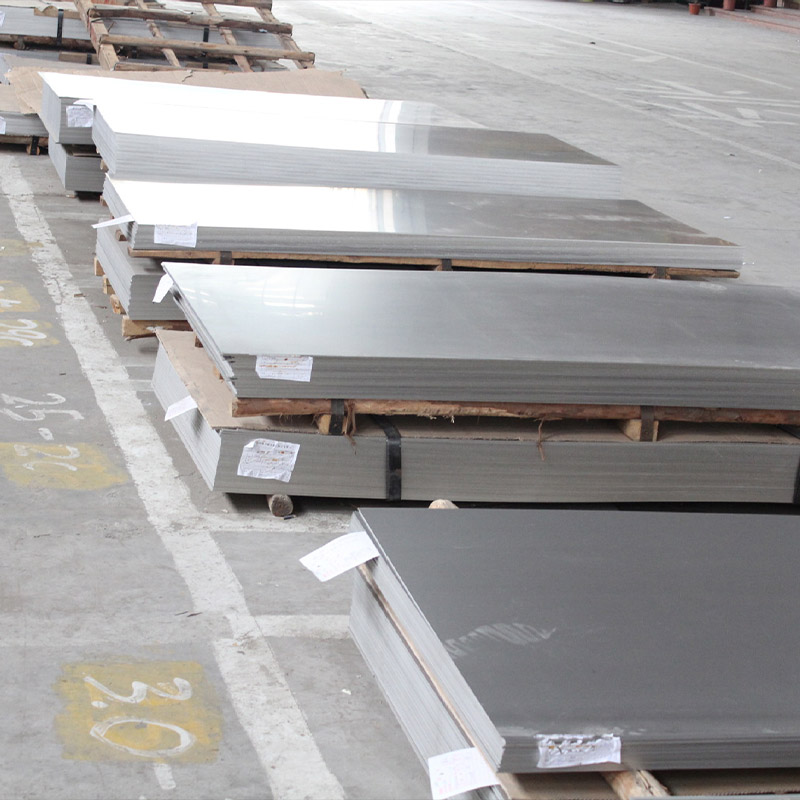

Ngokwendlela yokuvelisa, kukho iindidi ezimbini zokuqengqeleka okushushu kunye nokuqengqeleka okubandayo, kubandakanya ipleyiti encinci enobunzima obuyi-0.5-4 mm kunye neplate eshinyeneyo enobunzima be-4.5-35 mm.

Ngokweempawu zesakhiwo sebakala lensimbi, inokwahlulwa ibe ziindidi ezi-5: uhlobo lwe-austenite, uhlobo lwe-austenite ferrite, uhlobo lwe-ferrite, uhlobo lwe-martensite kunye nohlobo lokuqina kwemvula.

Amandla aphezulu epleyiti yentsimbi engenaziphene enokumelana nokugqwesa okugqwesileyo, ukugoba ukuqhubekeka kunye nokuqina kweendawo zokuwelda, kunye nokunyathela kwesitampu samalungu welding kunye nendlela yokuvelisa. Ngokukodwa, ipleyiti yensimbi engenasici equlethe i-Si, Mn, P, s, Al kunye ne-Ni enomxholo ofanelekileyo ongaphantsi kwe-0.02% ye-C, ngaphantsi kwe-0.02% ye-N, ngaphezu kwe-11% ye-Cr nangaphantsi kwe-17%, kunye ukuhlangabezana neemfuno ze-12 ≤ Cr Mo 1.5si ≤ 17, 1 ≤ Ni 30 (cn) 0.5 (Mn Cu) ≤ 4, Cr 0.5 (Ni Cu) 3.3mo ≥ 16.0, 0.006 ≤ C n ≤ 0.030 iya kufudunyezwa kwi-850 ~ 1250 ℃, kwaye ke unyango lobushushu luya kuqhutywa kwizinga lokupholisa elingaphezu kwe-1 ℃ / s. Ngale ndlela, inokuba ipleyiti yensimbi engenasici yamandla aphezulu kunye nomxholo we-martensite ongaphezulu kwe-12% ngomthamo, amandla aphezulu angaphezu kwe-730mpa, ukuxhathisa umhlwa kunye nokugoba, kunye nokuqina okugqwesileyo kobushushu be-welding indawo echaphazelekayo. Ukusebenza kwesitampu samalungu adityanisiweyo kunokuphuculwa kakhulu ngokusebenzisa kwakhona i-Mo, B, njl.