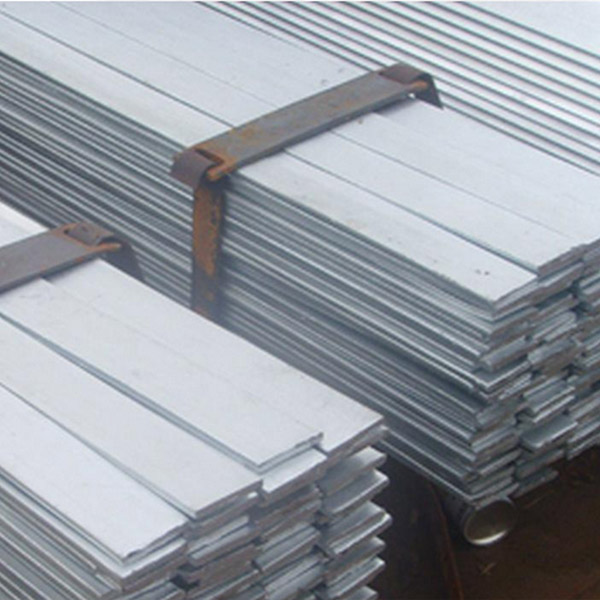

Intsimbi yentsimbi eyiGalvanized

Imigangatho: Ace, ASTM, bs, DIN, GB, JIS

Inqanaba: 304

Indawo yemvelaphi: Shandong, China

Igama leBrand: Jinbaicheng

Uhlobo: insimbi engenasici, ipleyiti yentsimbi ebandayo

Itekhnoloji: I-Hot Rolled / Cold Rolled

Unyango lomphezulu: ukuqhushumba kwesanti

Isicelo: iimveliso zetsimbi

Ububanzi: yenziwe ngokwezifiso

Ubude: yenziwe ngokwezifiso

Ukunyamezela: ±1%

Iinkonzo zokulungisa: ukuwelda, ukusika, ukubetha, ukusika

Ixesha lokuhambisa: iintsuku ze-7-20

Itekhnoloji: kushushu kuqengqeleka kunye nokubanda

Ubume: flat

Iimpawu: ubuso obugudileyo

Umphezulu: mnyama okanye igalvanized

Ukusetyenziswa 1: Ukwenziwa koomatshini

Usetyenziso 2: Amandla enyukliya

Ukusetyenziswa 3: Oomatshini bokutya

Intsimbi yecandelo yenye yeentlobo ezine eziphambili zentsimbi (ipleyiti, ityhubhu, iprofayili, ucingo). Ngokwesimo secandelo, intsimbi yecandelo ihlukaniswe ibe yintsimbi yecandelo elilula kunye necandelo eliyinkimbinkimbi yecandelo lensimbi (intsimbi yecandelo). Eyangaphambili ibhekisela kwintsimbi yesikwere, intsimbi ejikelezayo, intsimbi eyisicaba, intsimbi ye-angle, intsimbi ye-hexagonal, njl.; le yokugqibela ibhekisela kwi-I-beam, intsimbi yentsimbi, intsimbi yensimbi, intsimbi yefestile, intsimbi egobileyo, njl.

Intsimbi ethe tyaba enegalvanized ingasetyenziselwa ukwenza ii-ayini zehupula, izixhobo kunye namalungu omatshini njengempahla egqityiweyo, kwaye isetyenziswe njengendawo yesakhelo sendlu kunye neeescalators ekwakhiweni.

Inkqubo yokugaya

I-Hot-dip galvanizing ikwabizwa ngokuba yi-hot-dip galvanizing kunye ne-hot-dip galvanizing: yindlela esebenzayo yesinyithi yokuchasana nomhlwa, isetyenziswa ikakhulu kwizibonelelo zesakhiwo sesinyithi kumashishini ahlukeneyo. Iingxenye zetsimbi ezikhutshwe ngumhlwa zifakwe kwisisombululo se-zinc etyhidiweyo malunga ne-500 ° C, ukwenzela ukuba i-zinc layer ifakwe kwindawo yentsimbi, ngaloo ndlela ifezekise injongo ye-anti-corrosion.

Inkqubo yokucoca eshushu-diphu: imveliso egqityiweyo yokuchola-amanzi okuhlamba-ukongeza i-axiliary plating isisombululo-yokomisa-irack yokubeka-ukupholisa-amayeza-ukucoca-ukucoca-ukupholisa-shushu-diphu ukugqitywa kwegalvanizing

Ukugalela i-hot-dip galvanizing kuphuhliswa kwindlela endala yokudipha. Inembali yeminyaka eli-140 ukususela oko iFransi yafaka igalvanizing eshushu kwidiphu kushishino ngo-1836. Nangona kunjalo, ishishini lokugalela igalvanizing ediphu eshushu liphuhliswe ngomlinganiselo omkhulu ngophuhliso olukhawulezayo lwentsimbi eqengqelekayo eqengqelekayo kwiminyaka engama-30 edlulileyo.

1. Iimpawu zemveliso zikhethekileyo. Ubukhulu buyi-8-50mm, ububanzi buyi-150-625mm, ubude buyi-5-15m, kunye neempawu zemveliso zixinene, ezinokuhlangabezana neemfuno zabasebenzisi. Ingasetyenziselwa endaweni yeplate ephakathi kwaye inokudityaniswa ngokuthe ngqo ngaphandle kokusika.

2. Umphezulu wemveliso ugudile kwaye ucocekile. Inkqubo yokunciphisa amanzi ephezulu yoxinzelelo isetyenziswe kabini kwinkqubo yokuqinisekisa ukuba ubuso bentsimbi buhamba kakuhle kwaye bucocekile.

3. Amacala amile kwaye i-chestnuts yamanzi icacile. I-vertical rolling yesibini ekugqityweni kokugqiba iqinisekisa ukunyameka okulungileyo kumacala omabini, iikona ezicacileyo, kunye nomgangatho omhle womphezulu kumacala.

4. Umlinganiselo wemveliso uchanekile, ukwahlukana kwamanqaku amathathu, umlinganiselo ofanayo wezinga ungcono kunomgangatho weplate yensimbi; imveliso ithe tye kwaye imilo yepleyiti ilungile. Ukugqiba ukuqengqeleka kwamkela inkqubo eqhubekayo yokuqengqeleka, ulawulo oluzenzekelayo oluzenzekelayo, ukuqinisekisa ukuba akukho ntsimbi ifunjwe okanye yoluliwe, ukuchaneka komgangatho wemveliso kuphezulu, uluhlu lokunyamezelana, umahluko wamanqaku amathathu, umahluko womgca ofanayo, ukugoba kwerhengqa kunye nezinye iiparamitha. ngcono kunepleyiti ephakathi, kwaye imilo yepleyiti ithe tye. Idigri ilungile. Ukucheba okubandayo, ukuchaneka okuphezulu kokulinganisa ubude.

5. Imveliso yemveliso ithatha imigangatho yelizwe, efana namacwecwe ensimbi. Umgangatho kunye nemigangatho yobugcisa ihlelwe ngokwemigangatho ye-YB / T4212-2010 (Q345B / Q235B ibhekisela kwi-GB / T1591-94 kunye nemigangatho ye-GB / T700-88 ngokulandelanayo).

1. Amandla aphezulu, isakhiwo sokukhanya: igridi eqinile ye-welding ye-welding structure yenza ukuba ibe neempawu zokuthwala okuphezulu, ukwakhiwa kokukhanya kunye nokukhwela lula;

2. Imbonakalo entle kunye nokuqina.

| Into | Ixabiso |

| Umgangatho | Astm, bs, din, gb, jis |

| IBanga | Q235/q195/a36/ss400/s235jr |

| Indawo yokuzalwa | eTshayina |

| Uphawu | Ndimncinci |

| Iteknoloji | Ushushu uqengqeleke/unqunyulwa/ujikelezisa |

| Isicelo | Melana |

| Ububanzi | Yenzele okuthile |

| Ubude | Yenzele okuthile |

| Uyanyamezela | ±1% |

| Uhlobo | Yenziwe ngentsimbi eshayinayo |

| Inkonzo yokuqhuba | Ukuwelda, ukusika, ukubetha, nokunye |

| Ixesha lokuzisa | 7-20 iintsuku |

| Iteknoloji | Ubushushu buqengqeleke kwaye bubandayo |

| Umbala | Mnyama okanye igalvanized |

| Ubume | Intsimbi ecaba |

| Uphawu | Umphezulu ogudileyo |

| Amagama aphambili | Ipleyiti yentsimbi yengqondo |

| Ukusetyenziswa | Isinyithi / ukwakhiwa / iikhemikhali / isitya soxinzelelo |

Inkqubo yokuvelisa intsimbi ethe tyaba echanekileyo Umgaqo wokusebenza womatshini wokugqibezela intsimbi kukusebenzisa iiseti ezimbini zamavili agxadazayo ukuya phezulu nasezantsi ukuya kwinqanaba langaphambili kunye nenqanaba lokugqibela kwicala elingqingqwa loboya obubandayo bentsimbi; sebenzisa iperi yokugqitywa okucwangcisiweyo okuchaseneyo Amavili agxininiswe kwicala lobubanzi ukwenzela ukuba ububanzi bunyanzeliswe ukufezekisa iiparitha ezilindelekileyo, kwaye inani lokunyanzeliswa lihlengahlengiswa; sebenzisa amavili ama-5 agxadazayo ukulungisa ububanzi. Le nkqubo iqulunqwe kakhulu yibhokisi yokulawula, i-roller yokugqiba, iyunithi yokulinganisa kwangaphambili, iyunithi yokugqiba, kunye neyunithi yokulungelelanisa.

Inkqubo yemveliso ingashwankathelwa ngolu hlobo: ukulinganisa kwangaphambili → ukugqibezela → ukuqondisa → ukunyuswa kwasemva. I-Flat steel / a / b yintsimbi enobubanzi be-12-300mm, ubukhulu be-4-60mm, i-cross-section ye-rectangular kunye nemiphetho ecocekileyo. Intsimbi ye-Flat ingaba yimveliso yentsimbi egqityiweyo, okanye ingasetyenziselwa i-billet kwimibhobho edityanisiweyo kunye nee-slabs ezincinci zamaphepha afakwe. Isicelo esiphambili: Intsimbi ye-Flat ingasetyenziselwa ukwenza i-hoop iron, izixhobo kunye neengxenye zomatshini njengento egqityiweyo, kwaye isetyenziswe njengesakhiwo sesakhelo sokwakha kunye ne-escalator ekwakheni. Intsimbi ecaba yohlulwe yaziintlobo ezimbini ngokwemilo yayo: intsimbi ethe tyaba yasentwasahlobo ethe tyaba kunye necala elinye elinecala elinye eliphindwe kabini lentsimbi yasentlakohlaza. Intsimbi ethe tyaba eqengqelekayo eshushu isetyenziswa ikakhulu ukwenza imithombo yamagqabi yeemoto, iitrektara, uthutho lukaloliwe kunye nabanye oomatshini.

Indlela yenkqubo yentsimbi yasentwasahlobo yentsimbi yemoto

Intsimbi yentsimbi yasentwasahlobo yenziwa yinkqubo yokunyibilikisa isiguquli. Xa kuthelekiswa netekhnoloji ekhoyo, ineenzuzo ezilandelayo kunye neziphumo ezilungileyo:

1. I-Flat steel smelting kwi-converter ikakhulu isebenzisa isinyithi esityhidiweyo njengento ekrwada, enezinto ezimbalwa ezinobungozi kwintsimbi etyhidiweyo, kunye nomgangatho wentsimbi edibeneyo eveliswayo iqinisekisiwe.

2. Ngenxa yesivuno esiphezulu kunye nokusetyenziswa kwamandla aphantsi, iindleko ngetoni ziphantsi kunezo zombane zombane.

3. Intsimbi etyhidiweyo iphonswe ngokuthe ngqo kwiibhilidi, eziphelisa inkqubo yokuhlawula kunye nokunciphisa iindleko.

4. I-billet eqhubekayo yokuphosa inezinga eliphezulu lokusika-ubude, elinokuqinisekisa i-flat-steel cut-to-length rate kunye nokuhlangabezana neemfuno zabasebenzisi.